ETL 1110-2-343

31 May 93

requirements with respect to the appended structural

feature. Second, it is difficult to support the rebar

during RCC placement such that it will not dis-

place; and often it is difficult to devise a rebar

support system that does not interfere with form-

work and construction activities. Holes must be

provided in the formwork to accommodate the

anchorage extension and must allow enough flexi-

bility so the rebar can be placed at an RCC lift

surface where mortar bedding will be provided to

ensure complete rebar encapsulation. Rebar to be

installed during RCC placement should be provided

with a development length at least twice that

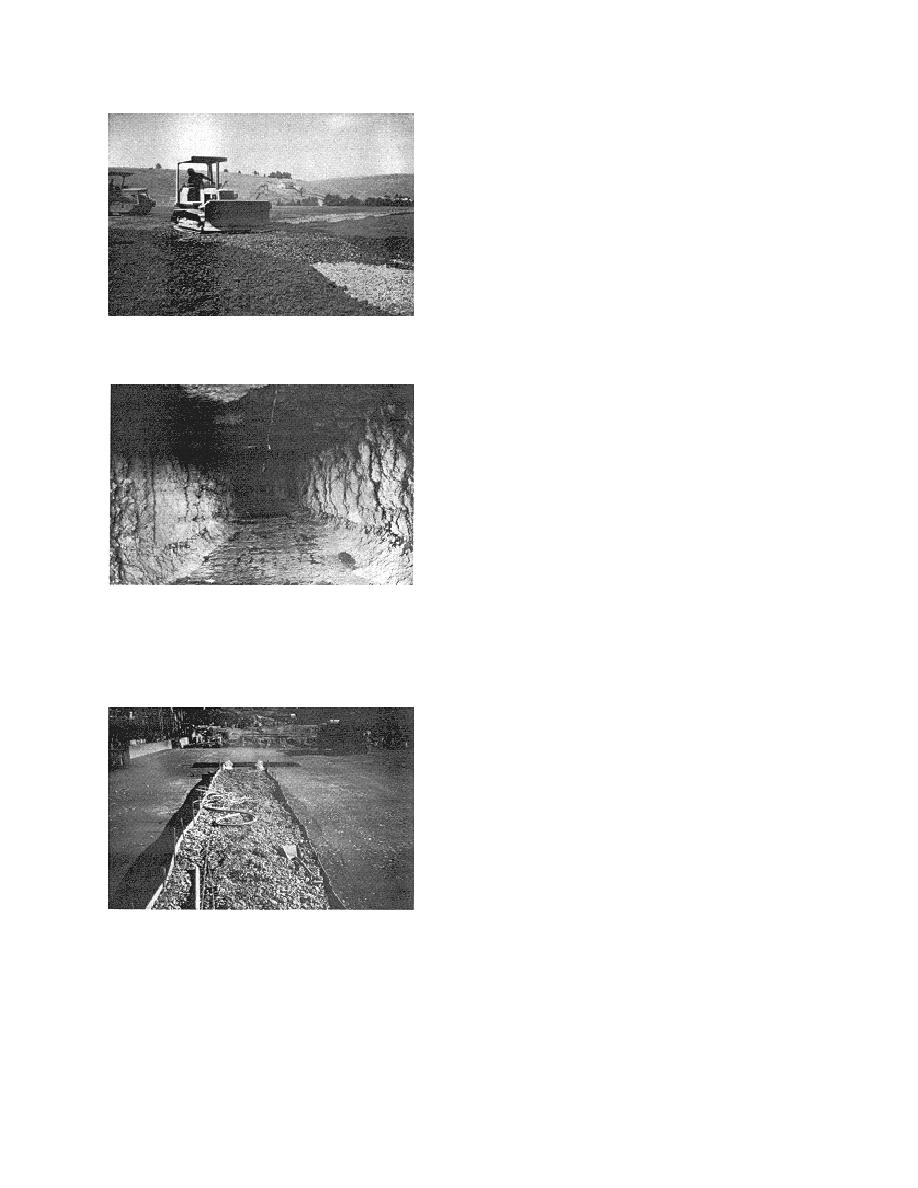

Figure 1-18. Gallery construction

required for top bars per ACI 318 in order to assure

full bond strength development. As an alternative,

anchorage reinforcement can be installed after RCC

placement by drilling and grouting. This procedure

is much more costly but does allow for more accu-

rate positioning of rebar and does ensure bar encap-

sulation and bond development.

(2) Structural reinforcement. RCC can and has

been placed with steel reinforcing. An example is

the spillway chute surfacing and apron for the

Toutle River Sediment Retention Dam. The RCC

for the spillway chute and apron was reinforced

with heavy welded wire mats. These mats were

provided in the RCC placement to: 1) prevent the

Figure 1-19.

After excavation of the

formation of wide cracks that might make the RCC

gravel/sand fill, protruding or loose RCC is

susceptible to deep abrasion erosion from ash-laden

removed. However, gallery walls are irregular

flood flows, 2) provide bending resistance to limit

and rough

cracking due to differential settlement, and 3) pro-

vide shear-friction resistance across cracks, to pre-

vent blocks of RCC, formed by perimeter cracking,

from being dislodged by flood waters. The welded

wire fabric is one innovative way of bringing the

strength and serviceability advantages of reinforced

structural concrete to an RCC placement. Another

means of improving RCC bending resistance might

be to place conventional reinforced concrete at the

extremities of an RCC placement where it is needed

to resist tensile bending stresses. This method

offers promise, but has not been used to date.

Reinforced RCC is shown in Figure 1-23.

7. Sampling and Testing Materials

Figure 1-20. Gallery construction using the

gravel/sand replacement method with wood

a. General. A comprehensive laboratory test-

plank forms to separate the RCC and

ing program is required to obtain the design mixture

gravel/sand fill to produce smoother, more

proportions for RCC strength and workability, to

uniform walls in the completed gallery

1-16

Previous Page

Previous Page