ETL 1110-2-343

31 May 93

Conference dated 10 June 1981), and flexural

strength (ASTM C78).

g. Direct shear strength, bond, angle of inter-

joints may be determined using laboratory-cast

cylinders, laboratory-cast blocks or panels, or sawn

blocks and drilled cores removed from the RCC

structure. The tests are made following procedures

described in the U.S. Army Corps of Engineers

Rock Testing Handbook (RTH), Method RTH 203-

80, "Direct Shear Strength of Rock Core Speci-

mens." Tests are normally performed using various

confining pressures, and typical test programs will

include the determination of cohesion (shear

strength at zero confining load) and the angle of

internal friction. With the use of appropriate dial

gages, residual sliding shear strength may also be

determined.

h. Post-construction evaluation. A post-

construction drilling and testing program should be

conducted on all major hydraulic structures to con-

firm that the as-built properties of the RCC are in

conformance with the design requirements. Drilling

of the completed structure should be scheduled a

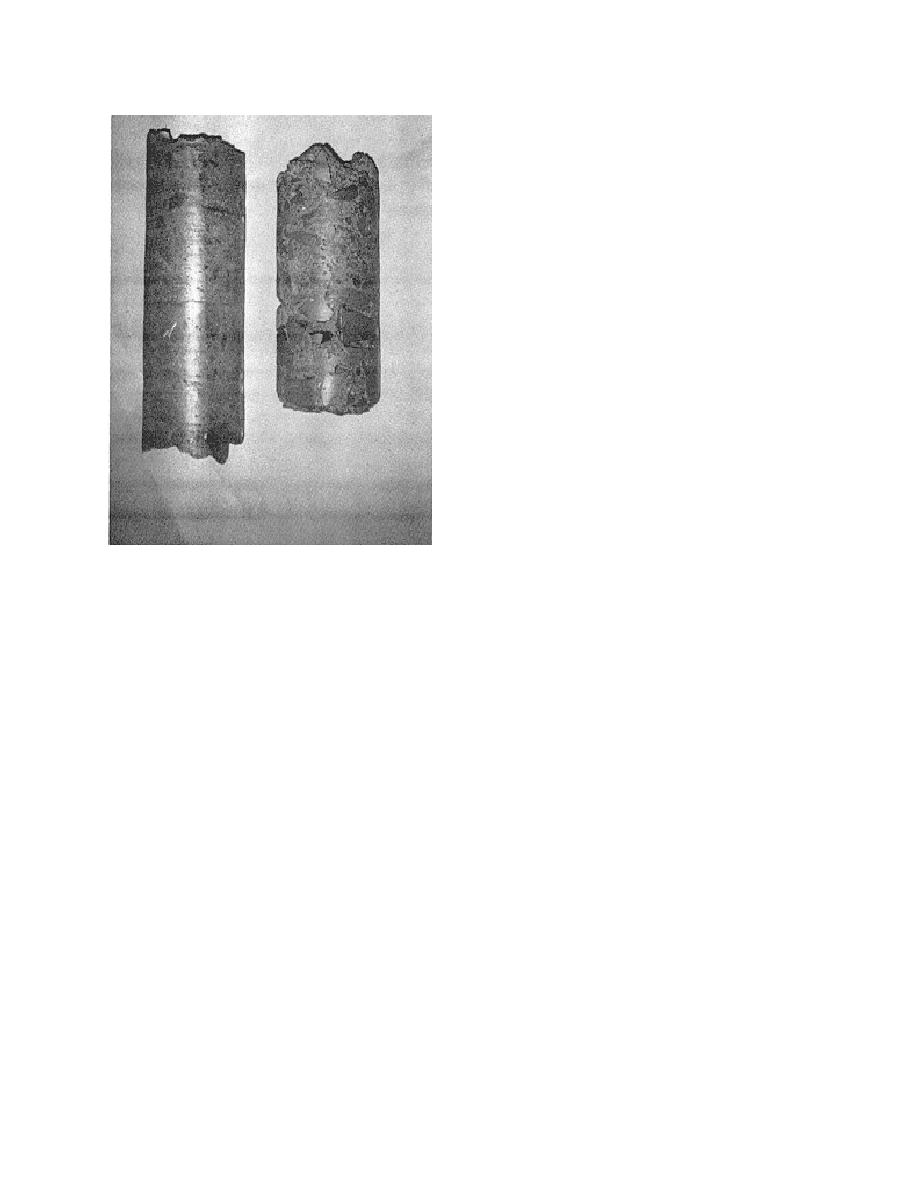

Figure 1-24.

Field core extracted from in-place

sufficient time after RCC placement as required to

RCC

assure adequate core recovery, but should be con-

ducted within 1 year of completion.

Cylinders are cured and capped using the same

Drilling should penetrate the full height of the struc-

procedures as for conventionally placed concrete.

ture at a sufficient number of locations to ensure a

f. Tensile strength. Direct tensile strength tests

statistically adequate sampling of the structure.

Testing should be conducted on the recovered cores

are made on cylinders, cores, or blocks using proce-

to confirm that: (a) lift joints meet structural

dures outlined in ASTM D2936, "Direct Tensile

requirements for shear and tensile strength, (b) the

Strength of Intact Rock Core Specimens." Speci-

RCC has the required compressive strength, and (c)

mens are cemented to steel end plates using high-

full uniform compaction has been achieved without

strength epoxy and moisture conditioned prior to

segregation. If an upstream zone of conventional

testing. Specimens with lift joints are tested with

concrete has been used, a majority of the core sam-

the lift joint centered within the middle third of the

ples should be taken far enough downstream to

tensile strength specimens. After testing, specimens

avoid intersecting the contact between RCC and the

are examined for type and location of failure,

conventional concrete. The results of the drilling

degree of bonded mortar, and aggregate failure.

and testing should be reported in the Post-Construc-

Since tensile strength is normally only between 5

tion Structural Report required by Section 9.d.

and 10 percent of the concrete compressive

strength, it is important that sufficient tests be made

8. Preliminary Structural Analysis Strength,

to ensure representative results. Other more indirect

Elastic and Thermal Properties

tests may also be made to determine or correlate

with tensile strength. These include: the tensile

a. General. Properties important to prelim-

splitting strength test (ASTM C496), the point load

inary structural investigations include compressive

tensile strength test (proposed method depicted in

strength, tensile strength, shear strength, modulus of

Proceedings of the International Construction Indus-

elasticity, Poisson's ratio, adiabatic heat rise and

try Research and Information Association

1-19

Previous Page

Previous Page