ETL 1110-1-189

14 Feb 03

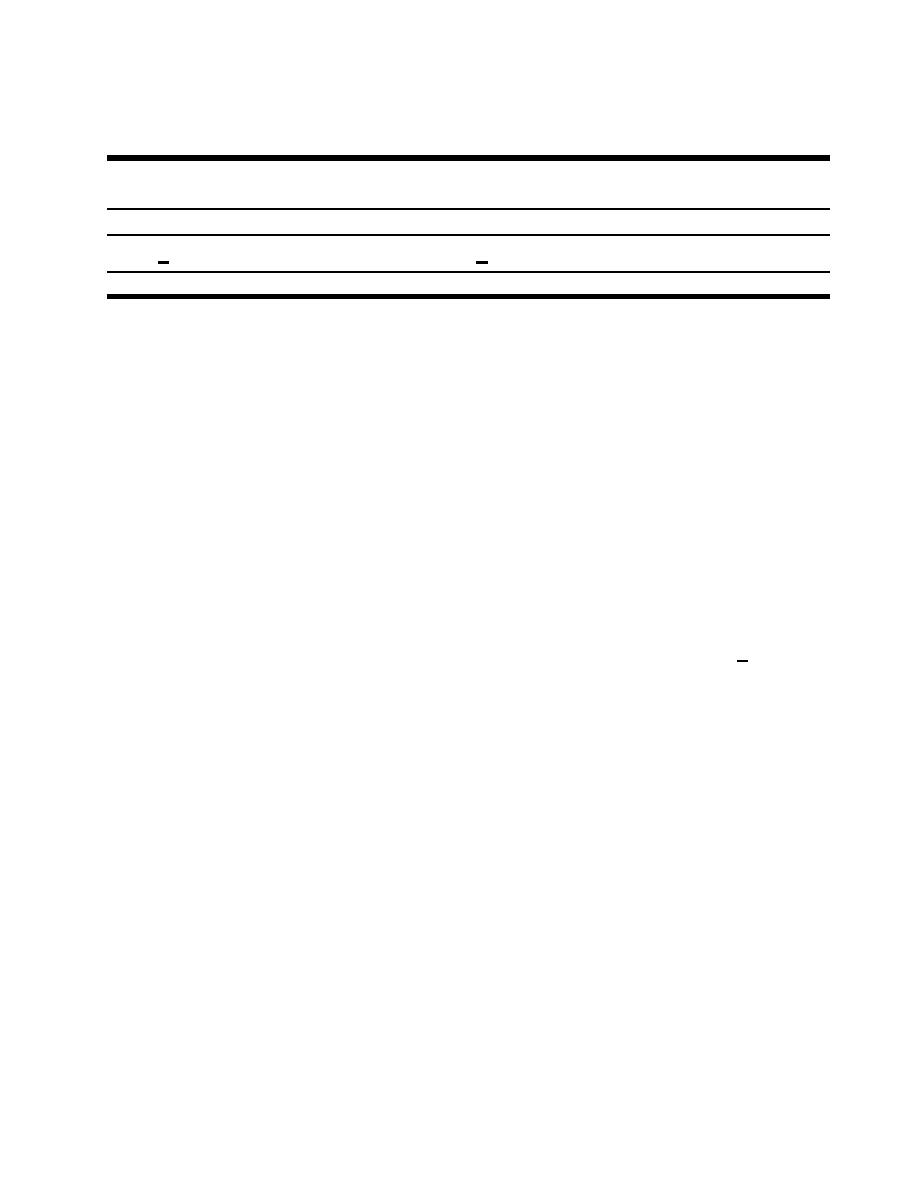

Table 9

Geosynthetic Overlap Requirements For Use Pavements

Step 1: Determine Design Subgrade Soil Strength and Geosynthetic Applicability

CBR < 1.0

1.0 < CBR < 4.0

CBR > 4.0

3 ft

2 ft

1 ft

6.2 Geogrid Installation

Prior to installation of the geogrid, the site should be cleared, grubbed, and excavated to the

design grade if not done previously for geotextile placement. As noted in Section 6.1, small

sections of geogrid can be used to cover roots, stumps, or stalks prior to geotextile installation to

reduce the potential for fabric puncture. Also noted in Section 6.1, stiff geogrids have been

successfully used as retrievable walking platforms to facilitate placement of the geosynthetic

separation and reinforcement layers. In this application, the stiff geogrid is unrolled along the

outer edges of the traffic lane to provide construction personnel with a temporary walkway to

unroll and place the reinforcement materials.

The geogrid should be rolled out by hand, ahead of backfilling, directly on the subgrade or

geotextile (if required) for design aggregate thicknesses less than 14 inches. For design

aggregate thicknesses in excess of 14 in., the geogrid should be placed in the middle of the

aggregate layer. For shallow-depth soft subgrades (CBR > 0.5), the geogrid is laid in the

direction in which the aggregate will be spread. For deep or very soft subgrades (CBR < 0.5),

the geogrid is laid transverse to the direction of the traffic lane. Table 9 should be used to

determine the appropriate overlap requirements, and the overlaps should be placed such that the

spreading of the aggregate base will not disturb the overlap distance. The geogrid can be held in

place using staples, pins, or sand bags for windy conditions.

6.3 Aggregate Placement

Vehicles must not be driven on the unprotected geosynthetics prior to aggregate placement.

For very soft subgrades (CBR < 1.0), an effective construction procedure is to install the

aggregate thicker and narrower than the design. Thus, the aggregate should be placed in the

center of the traffic lane at a depth greater than the final design grade. The weight of this

material will begin to displace excess water from the subgrade and begin subgrade consolidation.

This results in an increase in the overall subgrade strength beneath the traffic lane. After the

required amount of aggregate for the roadway and shoulders has been placed in the center of the

traffic lane, the excess aggregate can be spread laterally to the shoulders of the roadway until the

design grade is achieved. The aggregate material can then be compacted to the design thickness.

Care should be taken to spread the aggregate in the direction of the geosynthetic overlaps.

For subgrade CBR strengths between 1.0 and 3.0, the full design aggregate thickness should

be placed in one lift. Thinner lifts of aggregate run the risk of damaging the geosynthetics or

- 23 -

Previous Page

Previous Page