ETL 1110-2-344

31 Dec 93

APPENDIX C: ANALYSES WITH NO UPLIFT

1. Introduction

monolith and the foundation, it was required only to

reposition the pair of nodes on the monolith/

In an effort to simplify the comparison between the

foundation interface. The results of these analyses

are summarized in Table C-1. The variations of KI

traditional method of analysis and the finite

and KII over the range of crack lengths are shown in

element/fracture mechanics based analysis, a series

of analyses was performed for monolith 7E in

Figure C-1.

which the uplift pressure at the base of the monolith

was not considered (the culvert was considered in

(2) The final crack length computed using the

this case). Neglecting the uplift pressure greatly

traditional method of analysis was 9.55 ft. The

simplifies both the modeling of the structure and the

value of 8.58 ft computed using finite element

computation of the stress intensity factors. The

analysis and fracture mechanics is only 10.2% less

master and slave nodes required to model that

than 9.55 ft. When uplift was considered, the dis-

portion where the uplift pressure was applied as

crepancy between the final crack lengths was 43.7%

pore pressures (initial stresses) were not present in

(see Appendix A), which is over four times the

the mesh used for these analyses. Otherwise the

10.2% predicted for this case. The improved agree-

mesh was identical to the one shown in Figure A-4

ment in the predicted final crack lengths may be an

of Appendix A. The material properties and the

indication that the crack length of 8.58 ft is not

remaining applied loads for this investigation were

long enough to be strongly influenced by the cul-

not changed from those used for the analyses

vert. Even though the culvert is relatively large in

described in Appendix A in which uplift was

relation to the monolith, the influence that it would

considered.

have on the stresses and displacements at the base

of the monolith is greatest near the culvert and

decreases as the distance from the culvert increases.

2. Analysis and Results

Based on the observed results, the discrepancy

between the two methods of analysis would be even

a. Estimation of crack length.

less if both the culvert and the uplift were not

considered.

(1) A series of three analyses, each with a

b. Normal stress profiles.

different specified crack length, was performed to

compute an initial estimate of the final crack length.

(1) The normal stress profile along the base of

The prescribed crack lengths for these analyses

the monolith with a crack length of 8.58 ft and no

ranged from 6.0 ft to 9.0 ft in 1.5-ft increments.

uplift is shown in Figure C-2. In order to contrast

No analyses were performed for crack lengths grea-

ter than 9.0 ft because the value of KI was negative

the difference between the traditional and proposed

for a crack length of 9.0 ft and KI was positive for

methods of analysis, the normal stress profile from

all prior analyses. The final crack length of 8.58 ft

the traditional method of analysis is also included in

was found by re-meshing and comparing KI to KIc

Figure C-2. In comparing Figure C-2 (no uplift

as described in paragraph 3d(1) of Appendix A.

case) with Figure A-11 of Appendix A (full uplift

However, since initial stresses were not prescribed

case) the effect of the uplift on the normal stress

for elements adjacent to the interface between the

profile is minor considering the overall shape of the

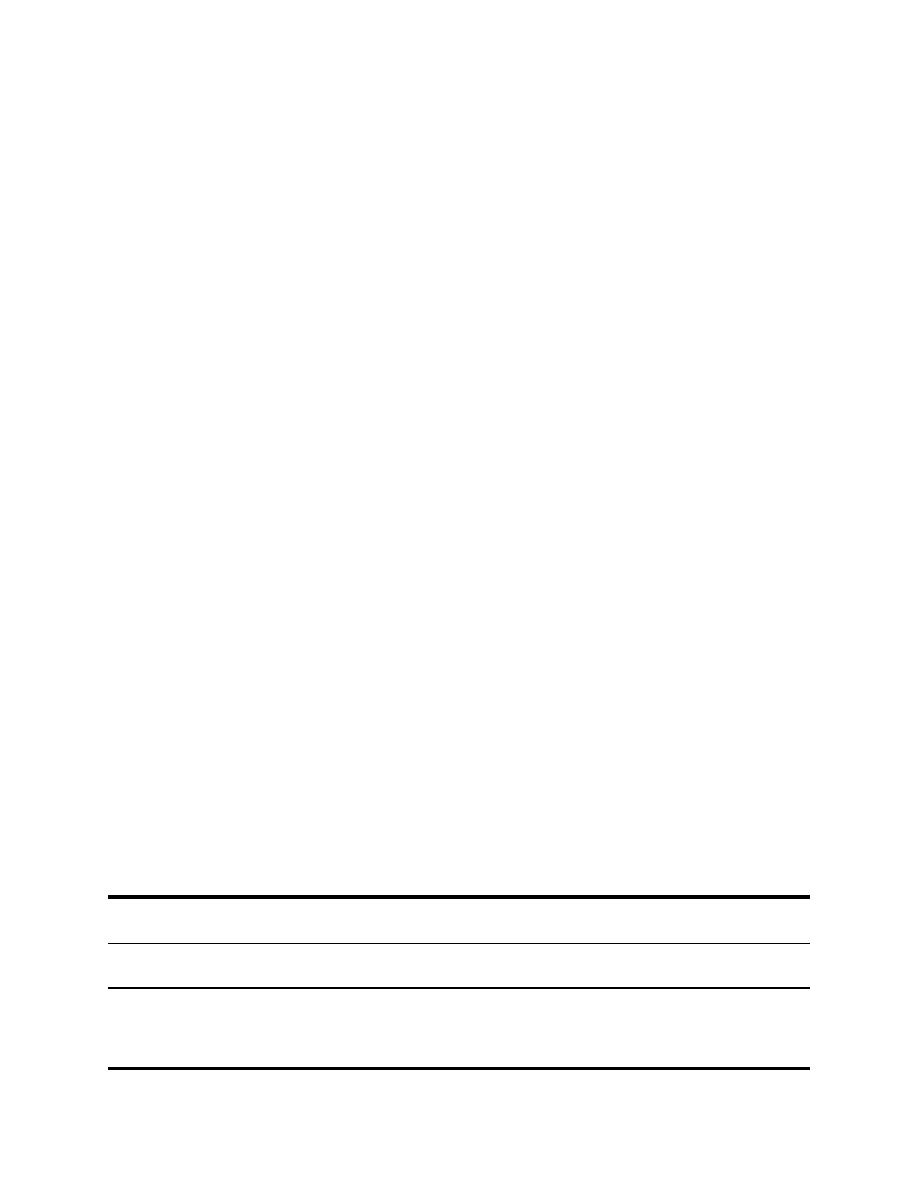

Table C-1

Summary of Finite Element Analyses With No Uplift

KI

KII

∆Hcrest

a

CMOD

ksi .

√in

ksi√ .

in

ft

in.

in.

6.00

0.411

0.536

0.00800

-0.0762

7.50

0.188

0.536

0.00843

-0.0777

8.58

0.000

0.547

0.00842

-0.0781

9.00

-0.132

0.578

0.00835

-0.0781

C-1

Previous Page

Previous Page