ETL 1110-2-344

31 Dec 93

curves. In all plots showing normal stress profiles

The line of action for the resultant force from the

(Figures A-11 of Appendix A, B-2 of Appendix B,

finite element analysis was 11.79 ft to the right of

and C-2), the normal stress near the crack tip is a

the toe as opposed to 11.82 ft from the traditional

relatively small negative value instead of zero.

analysis technique.

These errors in the normal stress are a consequence

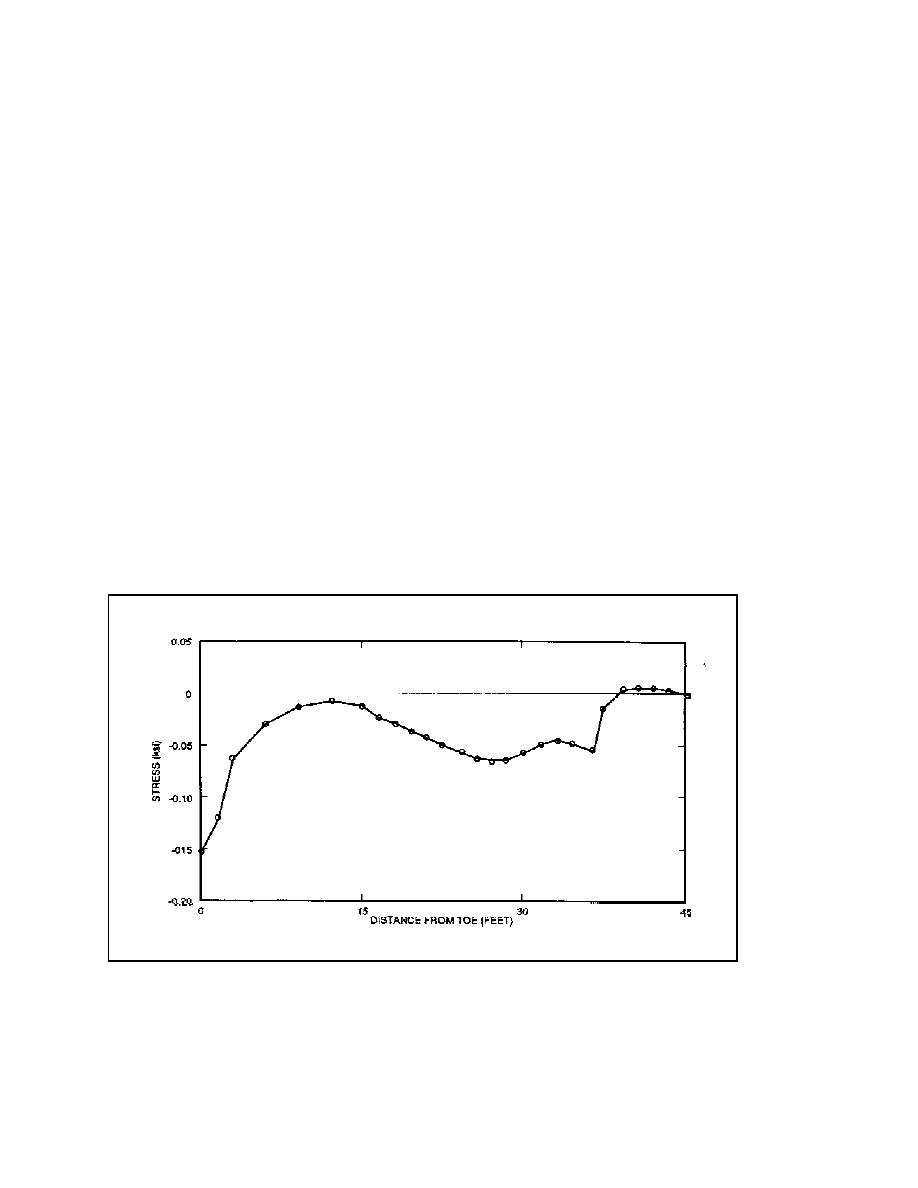

c. Shear stress profiles. The shear stress pro-

of the nodal strain projection technique, which is

very sensitive to the level of mesh refinement

file along the base of the monolith for a crack

length of 8.58 ft is shown in Figure C-3. In com-

around sharp corners and notches. However, the

paring Figure C-3 with Figure A-12 of Appendix A

normal stresses on the crack surface at a short dis-

the effect of the uplift on the shear stress profile is

tance away from the crack tip are zero in all cases.

minor in terms of the overall shape of the curves, as

This demonstrates that the effect of the crack tip on

was the case with the normal stresses. However,

the nodal stresses is indeed local and that the small

the shear stress profile in Figure C-3 does show a

error in the normal stress at the crack tip should not

slight increase between the right side of the culvert

be a cause for concern.

and the crack tip before going to zero on the crack

surface. It could be argued that this demonstrates

(2) The resultant force in the vertical direction

that the effect of the culvert on stresses (and dis-

and the line of action for the resultant force were

placements) at the base of the monolith may be

computed for the finite element solution and the

traditional analysis technique. Since uplift was not

limited to certain cases. The resultant force in the

considered, the actual estimated final crack lengths

horizontal direction was computed for the finite

for the two methods of analysis were used in these

element solution and the traditional analysis tech-

computations (with no uplift, the two systems are

nique. The resultant force from the finite element

equivalent force systems regardless of crack length).

analysis was 250.62 kips as opposed to 249.78 kips

The calculated resultant force from the finite ele-

from the traditional analysis technique.

ment analysis was 519.41 kips as opposed to

515.90 kips from the traditional analysis technique.

Figure C-3. Shear stress profile at the base of monolith for a = 8.58 ft: no uplift

C-3

Previous Page

Previous Page