ETL 1110-2-365

31 Aug 94

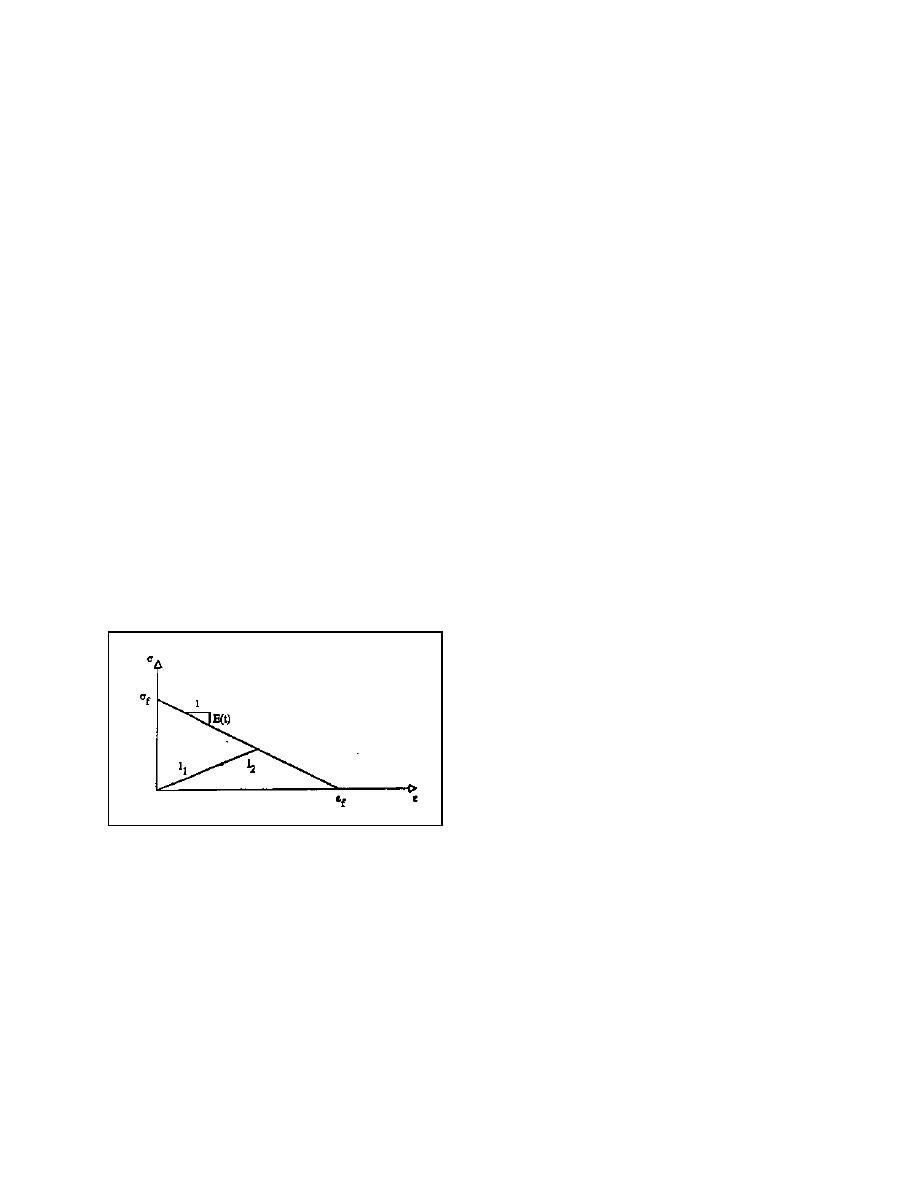

A2-3. Cracking Potential

c. If on or outside the surface, introduce a crack

perpendicular to the direction of the maximum princi-

Cracking potential is a quantitative measure of the

pal strain.

imminence of exceeding the cracking criteria. It is

equivalent to the ratio of l1 to the total length (l1 + l2),

d. In the direction perpendicular to the crack,

as shown in Figure A2-3, where l1 is the distance

the stress must then be set to zero, and the other

from the origin to the point (ε, σ) which reflects the

stresses must be modified to reflect that change.

actual principal stress and strain at a point in the

structure. The value (l1 + l2) is the length of the line

e. The stiffness matrix must then be modified to

from the origin to the failure surface which passes

reflect zero load carrying capabilities in that direction

through (ε, σ). The cracking potential is an indicator

until the crack closes and enters a compressive state.

of how near the current stress-strain state is to the

cracking surface.

f. If the material enters a compressive state, the

crack is assumed to have closed and 100 percent of

the compressive stiffness is reinstated in the direction

A2-4.

Computerized Procedure

perpendicular to the crack. Once the material is

placed in a tensile state again, the crack and a zero

The following is a brief step-by-step account of how

stress state is reintroduced at this location.

the cracking model operates within the code.

a. Plot the point represented by the principal

A2-5. References

stresses σ1 and σ2 and their respective principal

strains ε1 and ε2. Check if these points are inside or

a. Garner, S. B., Bombich, A. A., Norman,

C. D., Merrill, C., Fehl, B., and Jones, H. W. 1992.

outside the surface.

"Nonlinear, Incremental Structural Analysis of

Olmsted Locks and Dams - Volume I, Main Text,"

b. If inside the surface, no cracking occurs.

Technical Report SL-92-28, U.S. Army Engineer

The cracking potential is calculated, and the next

Waterways Experiment Station, Vicksburg, MS.

integration point is checked.

b. Truman, K. Z., Petruska, D., and

Ferhi, A. 1992. "Evaluation of Thermal and Incre-

mental Construction Effects for Monoliths AL-3 and

AL-5 of the Melvin Price Locks and Dams," Contract

Report ITL-92-3, U.S. Army Engineer Waterways

Experiment Station, Vicksburg, MS.

Figure A2-3. Cracking potential generation for a

specific cracking failure surface

A2-2

Previous Page

Previous Page