ETL 1110-2-534

30 Sep 94

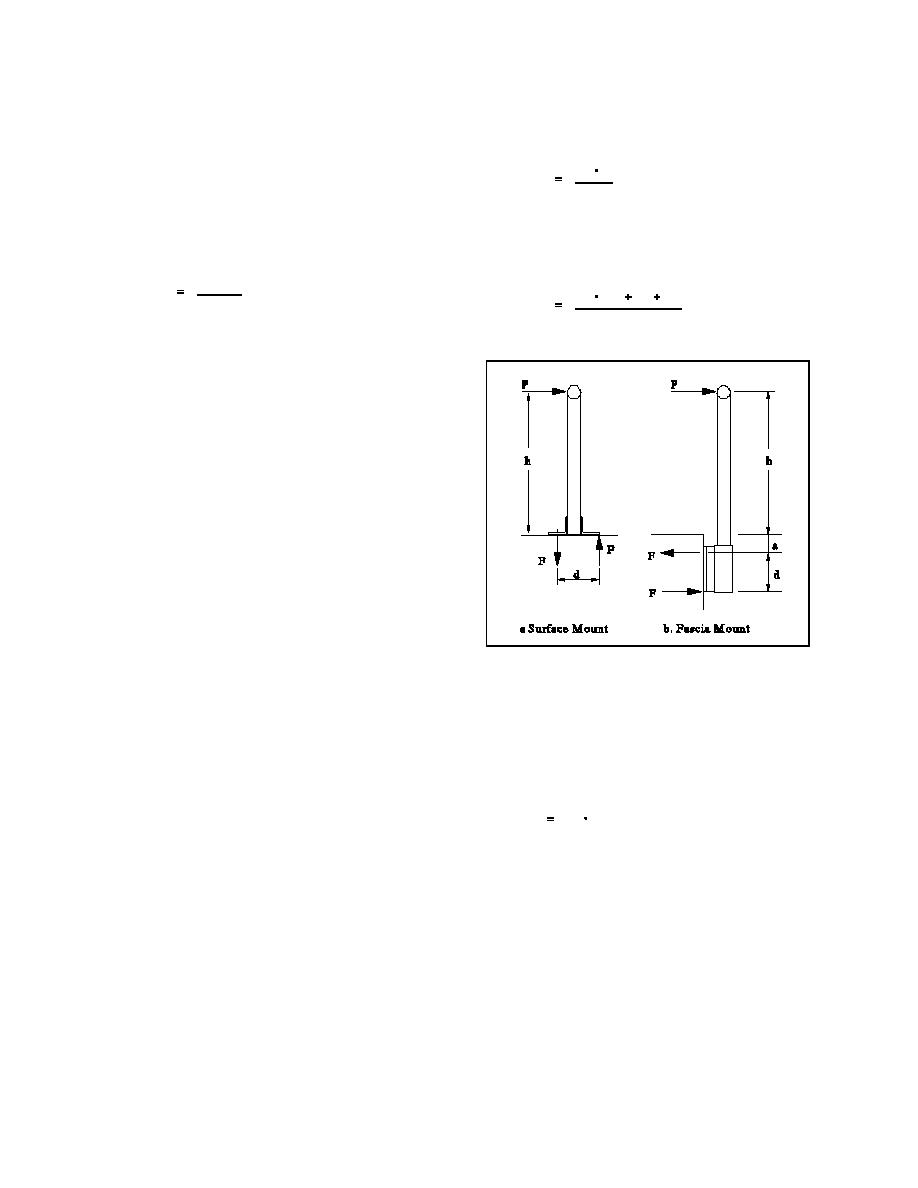

basically the same for all mounting arrangements

w

= railing load per unit length

and is calculated as:

K

= 8 for one or two spans

P

h

fapplied

K

= 9.5 for three or more spans

d

For all loadings, the applied bending stress fapplied is

for the mounting arrangement depicted in Fig-

calculated as:

ure A-3a, and as:

Mapplied

fapplied

P

(h

a

d)

S

fapplied

d

and compared to the allowable bending stress fallow

as discussed in paragraph A-2c above. The applied

stress should always be less than the allowable

stress.

h.

Anchorage analysis.

(1) While all of the above calculations may

show a guardrail system to be structurally safe, the

system will still be only as strong as the anchorage

to its supporting structure. Whatever the supporting

structure -- metal, masonry, or wood -- attachment

procedures are much the same; only the type of

fastener will vary. A railing can be mounted on the

fascia or stringer of a platform or stair, can be set

into the floor or stair tread, or can be mounted on

the floor or tread surface with a mounting fixture.

Figure A-3. Guardrail mounting methods

(2) When railings are set into concrete or

masonry floors or treads, the post receiving holes

for the mounting arrangement depicted in Fig-

should generally be at least 13 cm (5 in.) deep in

ure A-3b. A safety factor of 1.65 should be applied

order to provide ample post support. The edges of

to these values. The applied pullout force is then

the holes should be located at least 9 cm (3-1/2 in.)

compared to the allowable pullout force (supplied

from the edge of concrete or masonry. The ends of

by the manufacturer), which is calculated as:

the aluminum posts should be coated with bitumi-

nous paint, methacrylate lacquer, zinc chromate

primer, or other suitable coating to protect against

fallow

F

n

accelerated corrosion caused by contact with con-

crete, grout, or dissimilar metals. For railings

where n = number of fasteners in line. Because of

mounted on the surface of the floor or stair tread,

the uneven quality of concrete, it is recommended

either lateral bracing is required or a heavy-duty

that a safety factor of 4 be applied to the allowable

floor flange, designed to withstand the required

pullout force. However, many manufacturers have

loading and to support and reinforce the post, must

already applied appropriate safety factors to their

be used.

recommended pullout values, and additional safety

factors may not be necessary. The manufacturers'

(3) Required fastener capacity can be deter-

recommendations for anchor embedment length and

mined by computing the moment about a fastening

hole edge distance should also be carefully checked.

or support and comparing to the allowable bolt

pullout force, which is listed by the manufacturers

of the fasteners. The applied bolt pullout force is

A-7

Previous Page

Previous Page