ETL 1110-2-534

30 Sep 94

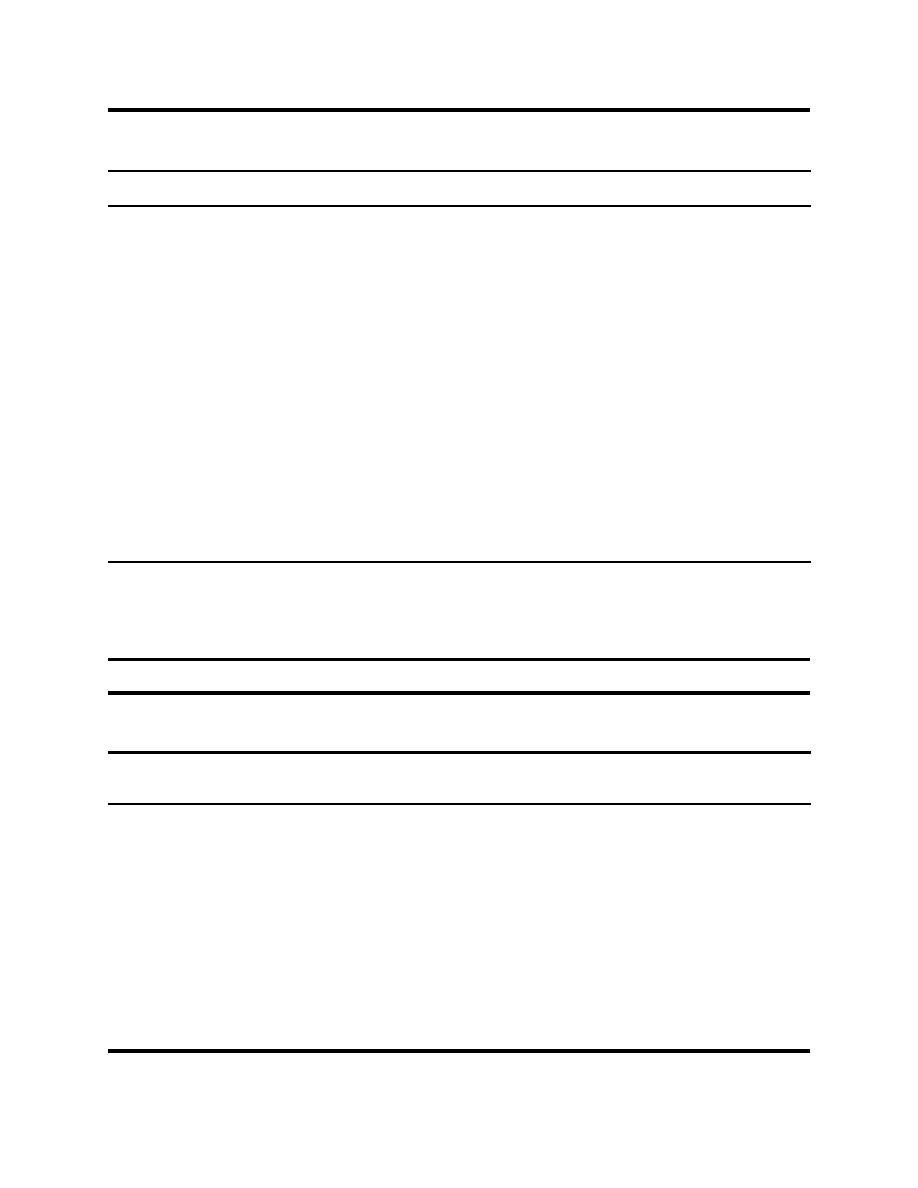

Table A-1

Mechanical Properties and Allowable Design Stresses

(Source: NAAMM and NOMMA)

Allowable Stress

Minimum Yield

Elastic Modulus

MPa x 103

Metal and Alloy

MPa

MPa

Carbon Steel Pipe:

A53, Type F

124

172

200

Types E and S, Grade A

149

207

200

Types E and S, Grade B

172

241

200

Carbon Steel Struc. Tubing:

A500, Grade A

164

228

200

A500, Grade B

207

290

200

A500, Grade C

228

317

200

A501

179

248

200

Aluminum Pipe:

6063 T5, T52

79*

110

69

6063 T6

124*

172

69

6063 T832

165*

241

69

6061 T6

165**

241

69

Stainless Steel Tubing:

Annealed, Types 302,

304, and 316

124

207

193

Unannealed Types 302,

304, and 316

207

345

193

Note: American Iron and Steel Institute (1985) specifies fb = 0.72fy. It also specifies that the diameter-thickness ratio of hollow

circular sections shall not exceed 3300/fy. For aluminum, allowable stresses are those specified by the Aluminum Association;

for stainless steel and copper, the allowable stresses shown are 0.60fy.

* Reduce allowable stress to 55 MPa within 25 mm of any weld.

** Reduce allowable stress to 97 MPa within 25 mm of any weld.

Table A-2

Pipe Section Properties

(Source: NAAMM and NOMMA)

Outside

Inside

Wall

Section

Moment of

Nominal

Schedule

Diameter

Diameter

Thickness

Area

Modulus

Inertia

mm2

mm3

mm4 x 103

Size

No.

mm

mm

mm

32

5

42

39

1.7

210

2,050

43

10

37

2.8

343

3,160

67

40

35

3.6

431

3,850

81

80

32

4.9

569

4,770

101

38

5

48

45

1.7

242

2,720

66

10

43

2.8

395

4,260

103

40

41

3.7

515

5,340

129

80

38

5.1

689

6,750

163

51

5

60

57

1.7

305

4,340

131

10

55

2.8

501

6,880

208

40

53

3.9

693

9,190

277

80

49

5.5

953

11,980

361

A-3

Previous Page

Previous Page