ETL 1110-2-544

31 Jul 95

soil model were obtained from the interpretation of

3-3. Case History: Birch Dam

tests performed in the drained and undrained triaxial

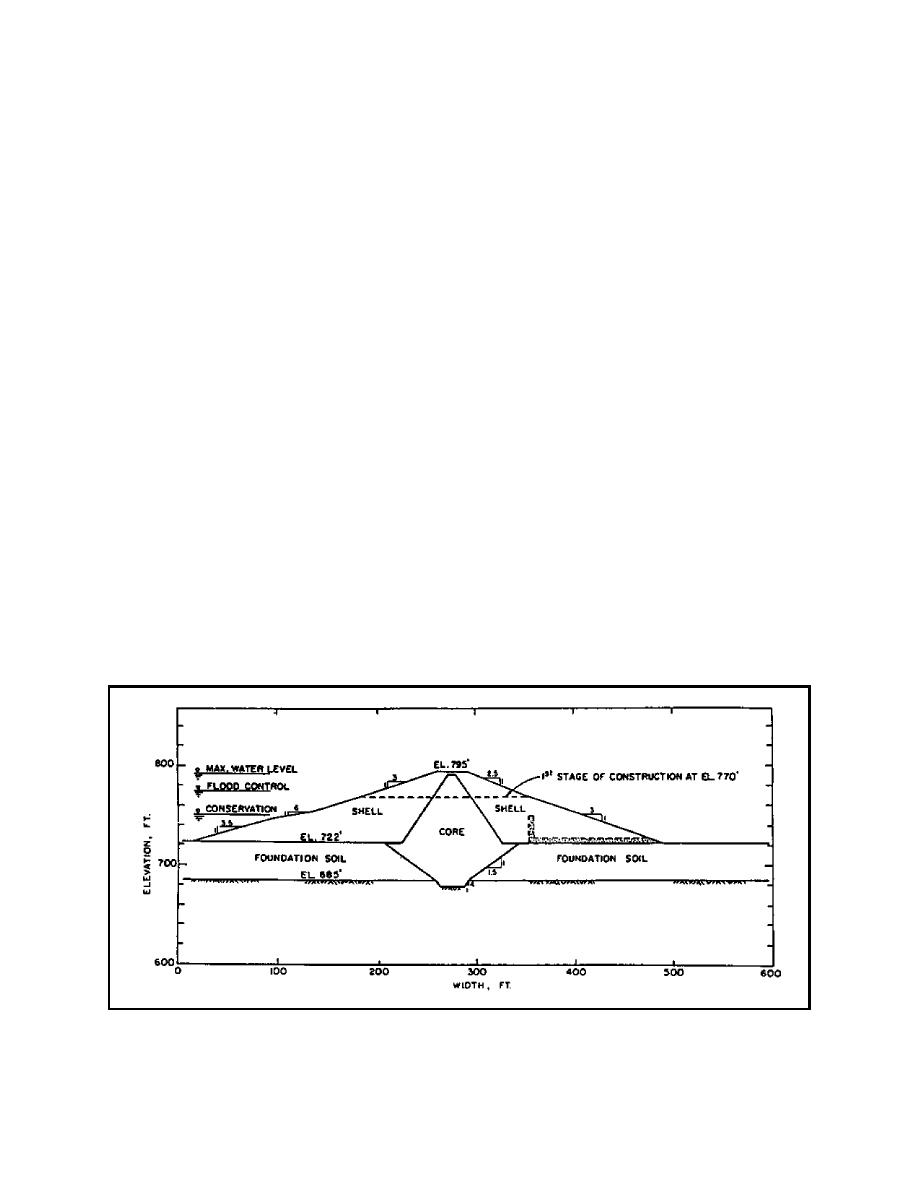

a. Project description. Birch Dam, built across

tests, respectively. All time dependent stresses and

Birch Creek between 1974 and 1976, has a maximum

movements were computed indirectly since ISBILD is

height of 70 ft and a crest length of 3,200 ft. The

a statics program which does not account for

embankment was constructed across alluvial soil

consolidation. Separate finite element analyses were

deposits which vary in thickness from 10-ft near the

performed to model the construction sequence for both

abutments to a maximum of 37-ft near the center of

drained and undrained conditions. These are extreme

the valley. A cross-sectional view of the

conditions in which the analysis is carried out

embankment is shown in Figure 16. The foundation

assuming that there is no dissipation of pore pressure

was primarily composed of compressible silts and

at all times for the undrained case and complete

clays with numerous lenses of silty and clayey sands.

dissipation of porewater pressures for the drained case.

The core and cutoff trench contain materials which

In this study, the authors contrived a scheme based on

clas-

Terzaghi's theory of consolidation to weight the

sify as a CL (according to the Unified Soil

drained and undrained cases to determine the dis-

Classification System). The upstream and downstream

placements and stresses in the embankment at any

shells contain coarser and less plastic materials which

time.

clas-sify as ML's. The finite element analysis of Birch

Dam was reported by Soriano, Duncan, and Simon in

d. Mesh details. The mesh used for both the

1976.

drained and undrained analyses is shown in Figure 17.

Only half of the mesh upstream of the centerline was

modeled in the analysis due to the symmetrical

b. Purposes. The finite element study of Birch

geometry of the cross section. A full mesh was used

Dam was performed to predict the stresses and move-

to model the filling of the reservoir because of the

ments in the embankment and foundation during con-

asymmetry of the loading conditions. Seepage forces

struction, at the end of construction, and after filling

were determined from a seepage analysis and applied

of the reservoir. The finite element analysis of Birch Dam

as concentrated forces to the appropriate nodal points

was reported by Soriano et al. (1976).

in the full mesh. The resulting movements and

stresses were then calculated.

c. Material model, properties, and finite element

Code. The hyperbolic model as implemented into

e. Construction sequence. The construction

ISBILD (predecessor to FEADAM), was used for the

schedule is presented in Figure 18. Both the drained

analysis of Birch Dam. The parameters for the

Figure 16. Cross-sectional view of Birch Dam

A-17

Previous Page

Previous Page