ETL 1110-2-550

30 May 97

F-3. Repair, Evaluation, Maintenance and

the past was made by collecting data on the current

Rehabilitation (REMR) Program

condition of equipment. This collection process, if

continued over time, could be used to develop life

a. The REMR research program is a 13-year,

history data and could then be used to develop

M research effort undertaken from 1984

failure rate and reliability data. The Hydroelectric

through 1997. The objective of the program was to

Power Equipment Condition Indicators program

identify and develop effective and affordable

was developed as the methodology used to collect

technology for maintaining and extending the

equipment condition data (Norlin et al. 1993). This

service life of civil works structures. REMR

program established a measure of equipment

products are useful in both major rehabilitation and

condition called the condition index with an associ-

nonroutine maintenance studies. The paragraphs

ated REMR Condition Index (CI) scale (see

below summarize some of the REMR products that

Table F-1) which may be a key step in the

have been used in reliability studies (U.S. Army

development of a reliability centered nonroutine

Corps of Engineers 1993).

maintenance program. The program also developed

the methodology used to objectively determine the

b. The REMR Management System is a

CI for (1) generator stators, (2) excitation systems,

computer-based system for managing REMR

(3) circuit breakers, (4) main power transformers,

activities. It is designed as a planning tool and an

(5) powerhouse automation systems, (6) turbines,

information system for project-level management.

(7) thrust bearings, (8) governor systems, (9) cranes

It establishes procedures to inspect and evaluate the

and wire rope gate hoists, (10) hydraulic actuator

conditions of civil work structures, provides data

systems, (11) emergency closure gates, and

management capabilities, and facilitates some

(12) power penstocks.

economic analysis of maintenance alternatives. The

d. The CI for a piece of equipment is deter-

REMR Management System was designed to help

prioritize REMR activities based on equipment

mined by evaluating a "condition indicator" which

condition, select maintenance alternatives based on

consists of standard tests or visual or other non-

performance, and compare the costs of maintenance

destructive examinations. The CI for a component

alternatives.

or system ranges from 0 to 100, where 0 index

indicates the component/system is in completely

c. Any decision which determines how to

deteriorated condition, and an index of 100 indi-

allocate rehabilitation dollars should be based on

cates the component/system is in new condition.

reliability data. An attempt to collect these data in

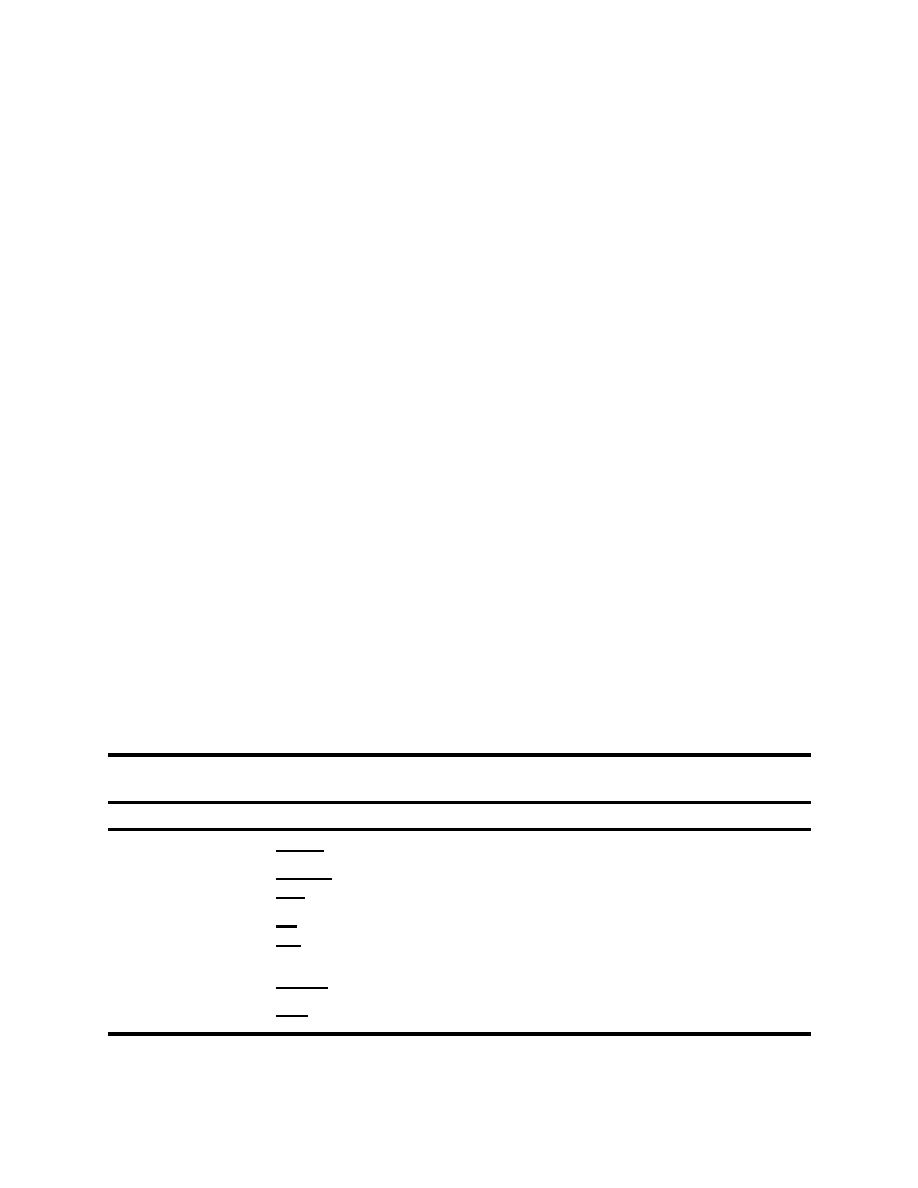

Table F-1

REMR Condition Index Scale

Zone

Condition Index

Condition Description

Recommended Action

1

85 to 100

Excellent: No noticeable defects.

Immediate action is not required.

Some aging or wear may be visible.

70 to 84

Very Good: Only minor deterioration or defects are evident.

2

55 to 69

Good: Some deterioration or defects are evident, but function is

Economic analysis of repair

not significantly affected.

alternatives is recommended to

40 to 54

Fair: Moderate deterioration. Function is still adequate.

determine appropriate action.

3

25 to 39

Poor: Serious deterioration of at least some portions of the

Detailed evaluation is required to

structure.

determine the need for repair,

Function is inadequate.

rehabilitation, or reconstruction.

Very Poor: Extensive deterioration.

Safety evaluation is recommended.

10 to 24

Barely functional.

0 to 9

Failed: No longer functions. General failure of a major structural

component.

F-2

Previous Page

Previous Page