ETL 1110-2-569

1 May 05

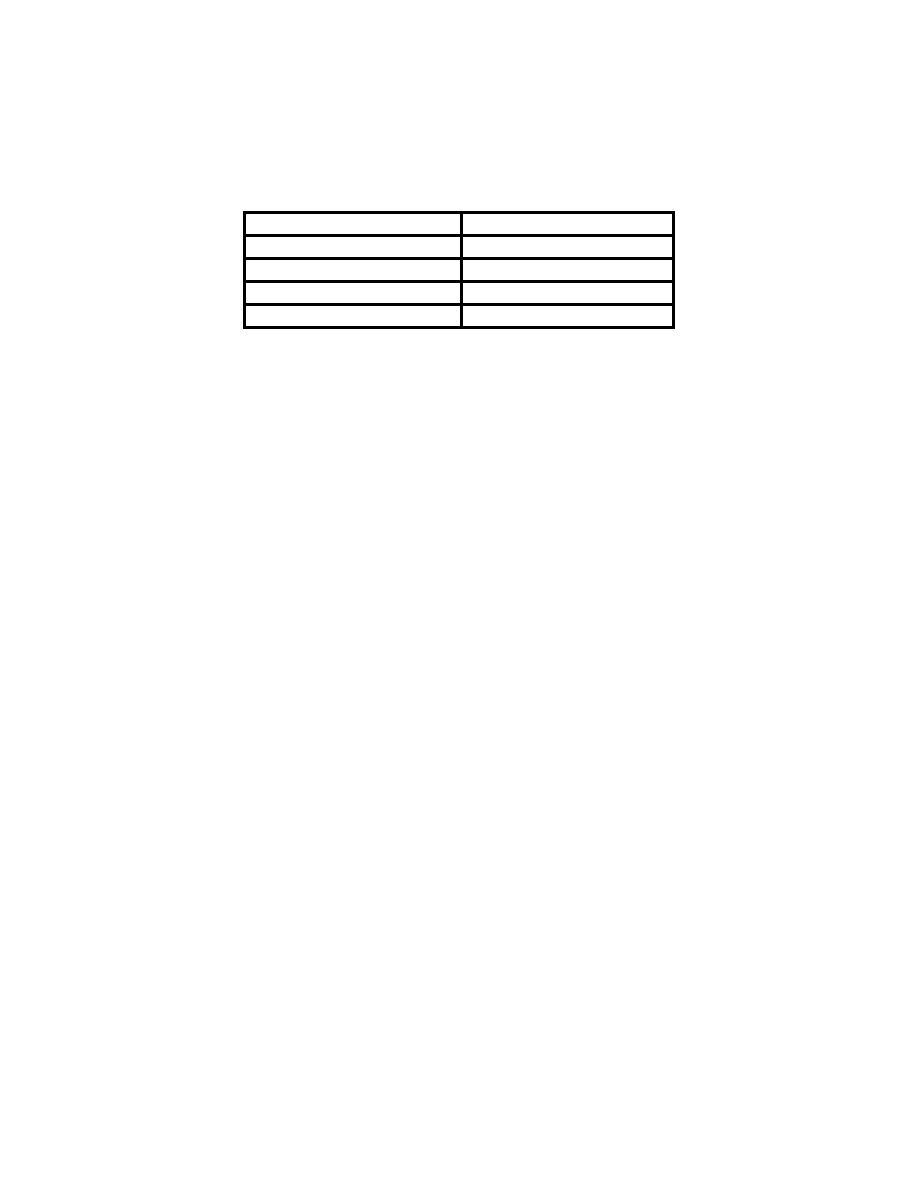

Table 1. Exit Gradient vs. Seepage Condition Trends

Exit Gradient, i

Seepage Condition

0 to 0.5

Light/no seepage

0.2 to 0.6

Medium seepage

0.4 to 0.7

Heavy seepage

0.5 to 0.8

Sand boils

The above data would appear to indicate that the gradient required to cause sand boils varies

considerably, and sand boils might even occur at an exit gradient of 0.5. However, the 1956

report explains these data as follows:

"...the gradient required to cause sand boils varies considerably at the different

sites, and relatively low gradients were recorded near some sand boil areas. This

may be due to the fact that at sites where sand boils developed previous to the

1950 high water, only fairly low excess head may have been required to

reactivate boils in 1950 and, as a relief of pressure occurs at the boil, readings of

Piezometers near the boil may be somewhat lower than those farther from the

boil."

This explanation has been overlooked in most reports. It is mathematically impossible to have a

first time sand boil in the top stratum with a saturated unit weight above 110 lb per cubic foot

and with an exit gradient less than 0.8.

b. History of Levee Seepage Design Guidance. Detailed design guidance for underseepage

design is presented in EM 1110-2-1913, Design and Construction of Levees. This guidance is

based on methods and equations presented in TM 3-424. These equations assume that the

foundation materials consisted of two soil layers, each of uniform thickness with horizontal

boundaries, a semi-pervious top stratum (blanket of silt or clay) with thickness z and a pervious

substratum (sands and gravels) with thickness d. Also, they assume that flow in the top blanket is

vertical and flow in the pervious substratum is horizontal. These assumptions are reasonable if

the horizontal permeability of the pervious substratum is at least ten times the vertical

permeability of the top blanket.

TM 3-424 presented methods and equations to be used in design of seepage control measures. It

recommended that seepage berms be designed by the following method:

"Seepage berms should have a width and a thickness such that i through the top

stratum and berm at the landside toe of the levee will not exceed 0.5, and at the

berm toe will not exceed 0.75 to 0.80. However, seepage berms need not have a

4

Previous Page

Previous Page