ETL 1110-2-343

31 May 93

RCC must also be sufficiently stiff to support haul-

ing, spreading, and compaction equipment; and

must contain adequate paste at the appropriate con-

sistency to become distributed throughout the con-

crete mass during mixing, placing and compaction.

RCC must contain sufficient mortar to prevent

segregation and fill large voids between coarse

aggregate particles. The paste is the binder that ties

the coarse and fine aggregates together. In a plastic

state, the paste provides cohesion and workability to

the RCC. In a hardened state, the paste content and

quality will dictate the concrete strength, bonding

potential, permeability, and durability. The paste

volume is proportioned to fill the void system of the

fine aggregate. Typically, fine aggregate has a void

content ranging from approximately 35 to 40 per-

cent. The minimum paste-to-mortar volume ratio

(Vp/Vm) specified in EM 1110-2-2006 ensures that

voids in the mortar fraction are completely filled.

Guidance for typical RCC mortar contents are also

given in EM 1110-2-2006 (Reference 12c).

b. Water-cement ratio. The compressive

strength of RCC depends primarily on the water-

cement ratio and degree of compaction. For RCC

that is fully consolidated, the compressive strength

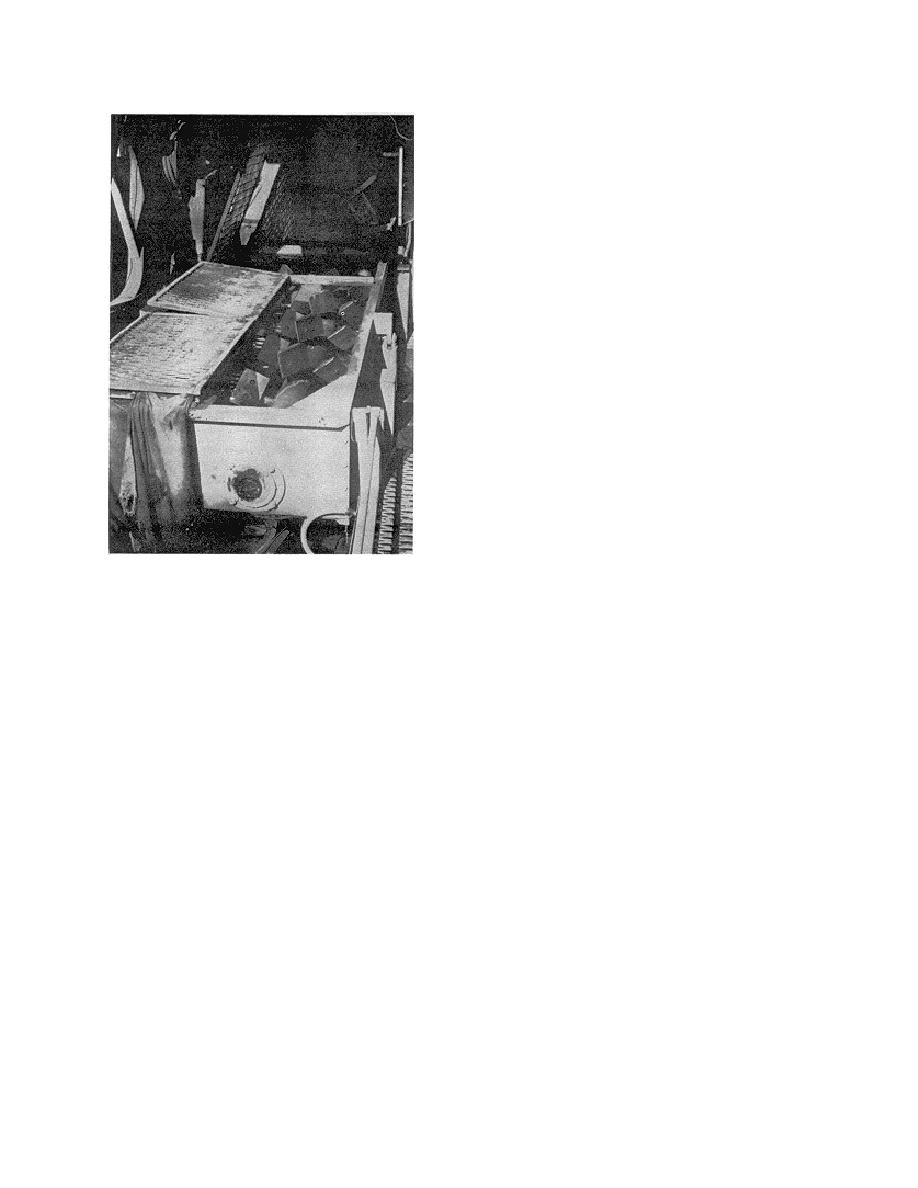

Figure 1-3. Pugmill mixing chamber. Paddles

will increase as the water-cement ratio decreases.

are mounted on horizontal shafts in the

Water-cement ratio guidance for conventional con-

pugmill mixing chamber. The paddles can be

crete is given in EM 1110-2-2000, "Standard

adjusted or replaced as required to maintain

Practice for Concrete" (Reference 12b). In this

mixing efficiency

guidance, the maximum permissible water-cement

ratio is provided for various anticipated exposure

conditions of the structures. Water-cement ratios

The Corps has used RCC for the construction of

should be selected during the laboratory mixture

gravity dams, a lock floor at New Cumberland Lock

design phase to meet all strength and durability

and Dam, in place of riprap for erosion protection

requirements.

downstream of a floodwater sill on the Chena Pro-

ject, as erosion protection for the Toutle Sediment

c. Aggregate quality and gradation. Aggre-

Retention Structure, at the Bonneville Project to

protect weak foundation rock from weathering, and

gates for RCC should meet the same high standards

as navigation lock guide/wing walls. RCC has also

for quality and grading as required for conventional

been used for emergency repairs of a check dam

concrete. Only where extraordinary circumstances

exist, such as construction during an emergency

and as a spillway through an earthen sediment

situation in which use of a poorer quality does not

retention dam on the Toutle River. RCC can and

prevent meeting design quality requirements of the

has been used for stilling basins, plunge pools,

concrete, could aggregates of a lesser quality be

spillway repair and replacement, foundation mats,

justified. Coarse aggregates for RCC are graded to

diversion walls and open channel lining.

standards identical to those for conventional mass

5. Mixture Proportions and RCC structural

concrete; however, the fine aggregate used for RCC

Properties

will normally contain a greater proportion of mater-

ial passing the No. 200 sieve in order to fulfill paste

a. Paste and mortar content. RCC mixtures

and workability requirements. RCC containing

must be workable, free of segregation, and easily

minimally processed pit run aggregate may require

a greater water content, be less durable, have a

compacted using external vibratory rollers. The

1-3

Previous Page

Previous Page