ETL 1110-2-344

31 Dec 93

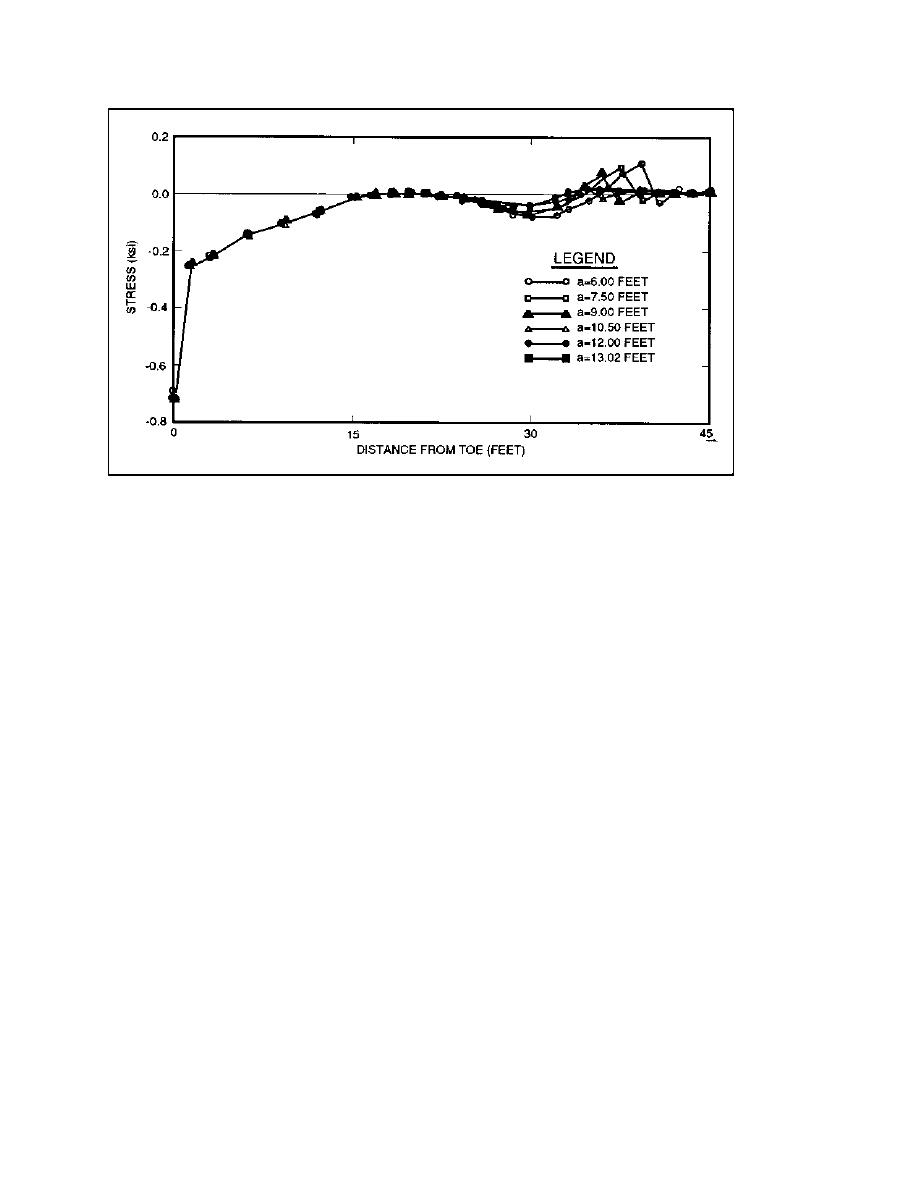

Figure A-10. Normal stress profiles at the base of the monolith

performed to determine the line of action for the

(b) The normal stress profiles along the base of

resultant forces from the two methods of analysis.

the monolith for the final crack lengths predicted by

The line of action for the resultant force from the

both the finite element analysis and the traditional

finite element analysis was 7.60 ft to the right of

method of analysis are shown in Figure A-11. The

the toe as opposed to 7.29 ft from the traditional

effective stress is plotted as a function of distance

analysis technique. Confidence in the finite element

along the base of the monolith (with the toe located

analysis is provided since the results show a good

at zero) and the negative sign on the stresses indi-

correlation between the two methods of analysis.

cates compression. The stress computed from the

finite element analysis was integrated along the base

(5) Shear stress profiles. The shear stress pro-

using the Trapezoidal rule to determine the resultant

file along the base of the monolith for a crack

force in the vertical direction. In order to assess the

length of 13.02 ft is shown in Figure A-12. The

accuracy of the finite element analysis, the resultant

integrated stress was computed to determine the

force was also computed for a crack length of

resultant force in the horizontal direction resulting

13.02 ft using the assumed stress distribution of the

in a value of 247.82 kips. Comparison to

traditional analysis technique. The crack length of

249.78 kips from the traditional method of analysis

13.02 ft was used in this computation rather than

shows a good correlation.

the predicted crack length of 23.13 ft because the

uplift forces are a function of the crack length and

(6) Vertical displacement profiles. The verti-

any other crack length would result in nonequiva-

cal displacement profiles along the base of the

lent force systems. A crack length of 13.02 ft

monolith for crack lengths of 6.0 to 13.02 ft are

yields a tensile stress at the crack tip using the

shown in Figure A-13. The vertical displacement

traditional analysis technique. The tensile stresses

were included in calculation of resultant forces

profiles are virtually identical for distances along

because this comparison is between two equivalent

the base of the monolith up to 20.0 ft. Beyond

force systems, not systems with equivalent crack

20.0 ft, the vertical displacement profiles diverge.

lengths. The resultant force from the finite element

The explanation for this phenomenon follows the

analysis was 416.64 kips/ft (kips per foot width) as

same line of reasoning as that for the behavior of

opposed to 414.37 kips/ft from the traditional analy-

the normal stresses along the base of the monolith,

in which the culvert near the interface between

sis technique. Similar computations were also

A-12

Previous Page

Previous Page