ETL 1110-2-365

31 Aug 94

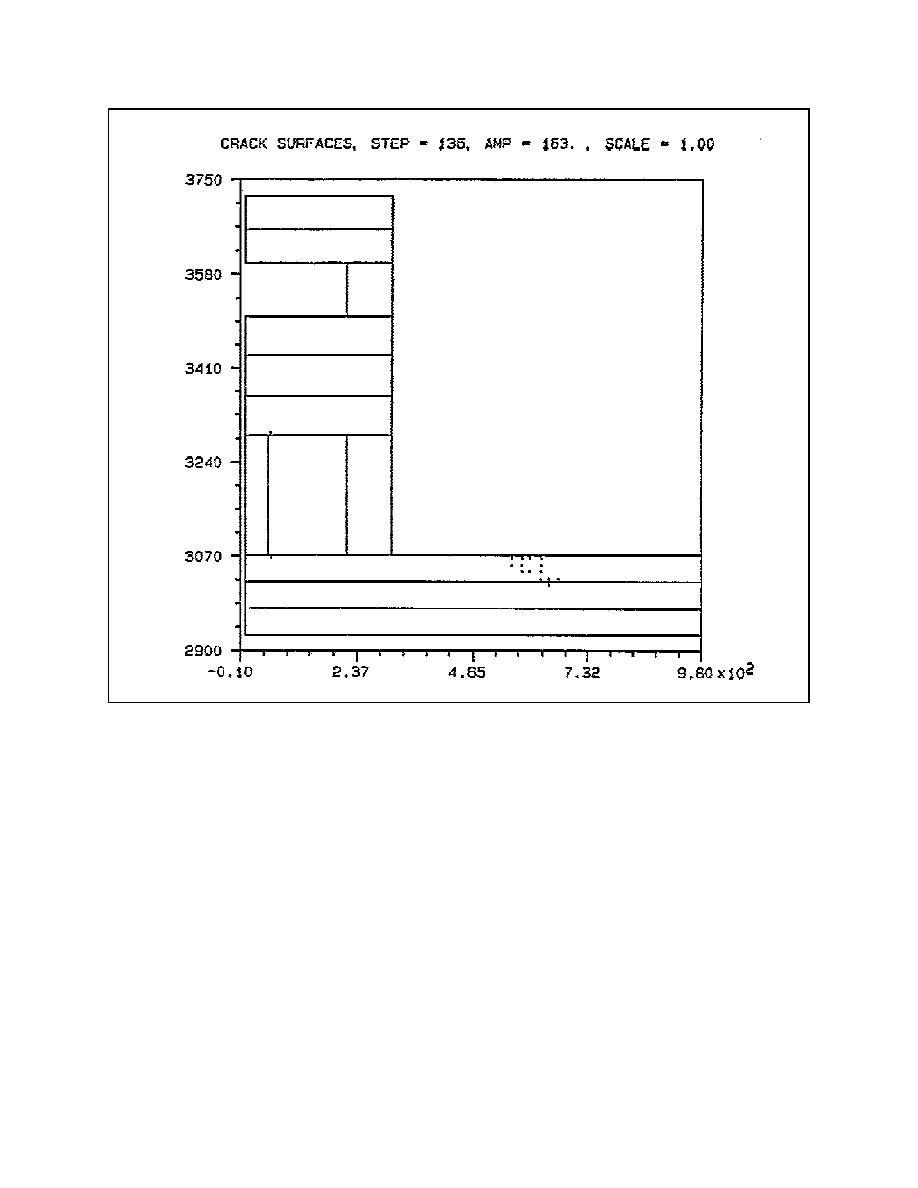

Figure B-5.

Crack plot at day 163 of the middle wall half of the chamber monolith model

would create the worse condition, but Figure B-22

(designated in the plots by "Extreme Ambient"), node

3371 near the top of the slab follows the ambient

shows that this is not the case in this instance. The

maximum stress for the 60 oF placing temperature

much more closely than the other two curves. If the

plots from the three figures were superimposed upon

case is approximately 80 psi higher than the maxi-

one another, a substantial temperature gradient would

mum stress at this point for the ambient placing

occur from the top to the bottom of the slab at

temperature case. While these results do not match

approximately day 200.

conventional understanding from analysis of mass

concrete structures, there is a logical explanation.

(2) Stress results. Plots of stress used in evaluat-

The results shown in Figure B-22 are essentially a

ing the results are shown Figures B-22 through B-26.

surface effect as shown in the stress distribution plot

Figure B-22 is a time-history plot of the horizontal

in Figure B-23. Surface effects cause the stress to be

stress at the point of maximum stress in the chamber

lower for the ambient placing temperature, but at

monolith. As mentioned previously, in the past it has

other points through the slab thickness this is not

been assumed that a higher placing temperature

necessarily the case. A time history at the second

B-7

Previous Page

Previous Page