ETL 1110-2-533

30 Sep 94

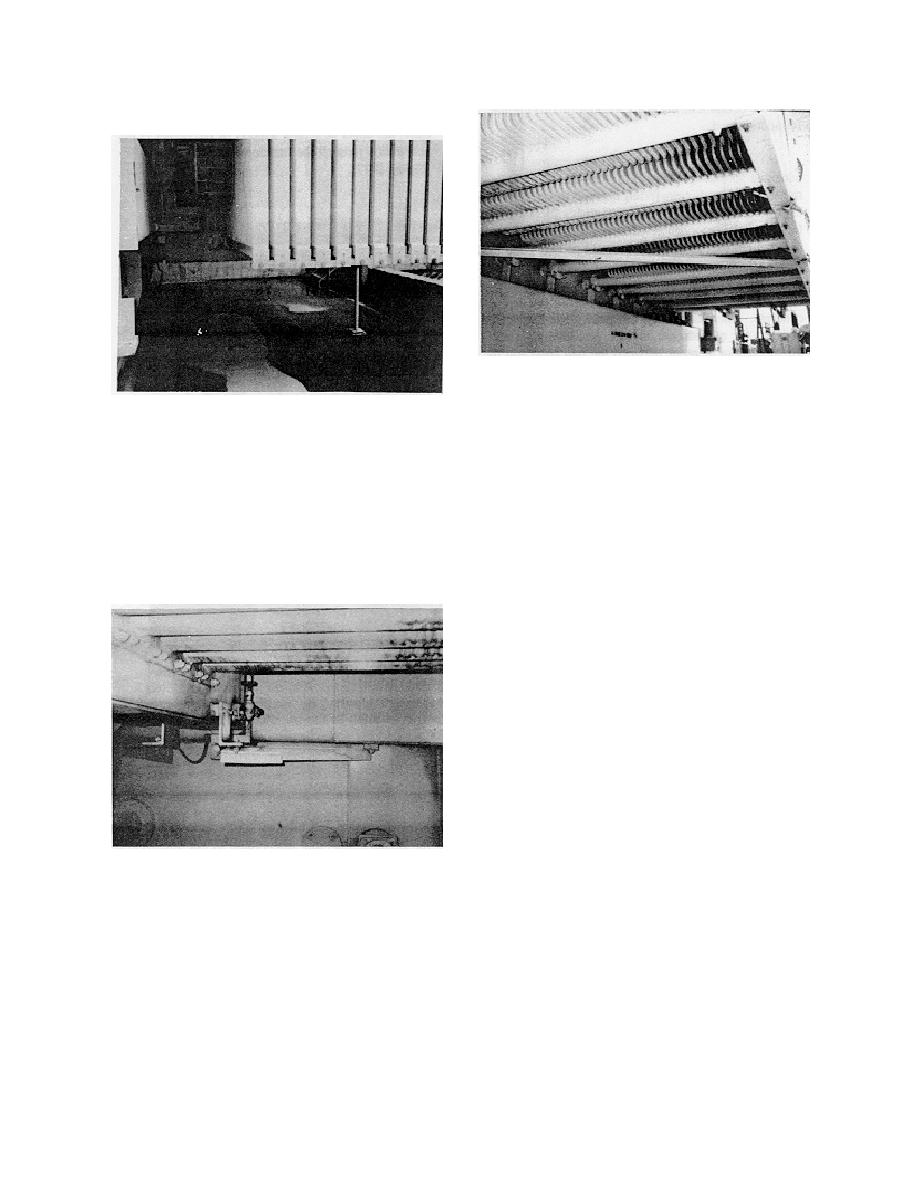

Figure B-30. Individually supported cooler ele-

ments. Each cooler element has its own trans-

former case penetration which also serves to

Figure B-28. Cooler elements mounted to a mani-

support the cooler. Flange leaks have not been

fold. Individual cooler sections are mounted to a

observed for this type of configuration. The end of

manifold which is connected to a flange forming

the coolers which is most distant from the trans-

the transformer case penetration. The cooler does

former body is also restrained by a small angle

have a vertical support and a small diagonal brace.

iron brace

Lateral motion exerts large moments on the flange

causing oil leaks. A simple modification is to add

angle iron brace between the outside end of the

(q) It is relatively easy to add lateral and vertical

manifold and the corner of the transformer case

braces; however, it is important that they are both

strong and rigid. These braces should be provided at

both the bottom and the top of the coolers. Vertical

braces must reduce the load on the upper transformer

case penetration; thus, they must be connected

between the transformer case and coolers and/or the

manifold.

(r) Some transformers are designed with substan-

tial cooler supports, and the piping connection to the

transformer case penetration is relatively flexible

(Figure B-31).

(s) Transformer-mounted surge arrestors fre-

quently fail. In general, when this occurs they can be

removed from the system and replaced later when

spare parts and time are available. A more serious

concern about the failure of the surge arrestor is that

Figure B-29. Bracing of lower cooler manifold. A

it can damage a transformer bushing when it falls

diagonal angle iron serves as a brace between the

after it fails. The configuration of the bus connection

transformer body and the cooler manifold. Note

between the surge arrestor and the bushing usually

that the connection to the manifold is through an

controls this interaction.

angle. While this may be strong, it is very flexible

so that the cooler assembly is not adequately

(t) Oil leaks at bushings and, less frequently,

restrained, and large moments can be applied to

bushing failures can put a transformer out of service.

the flange on the transformer case penetration

At this time there is no effective remedy for this,

B-18

Previous Page

Previous Page