ETL 1110-2-563

30 Sep 04

Table C-2

Lognormal Distribution Parameters for Impact Variables at Winfield Upper Approach

Guard Wall

Design Structure

Variable

Mean

Standard Deviation

Minimum

Maximum

θ, deg

Upper approach guard wall

9.3

3.75

0

30

V, ft/sec

1.08

0.7

0

10

Upper Guide Wall

River Flow

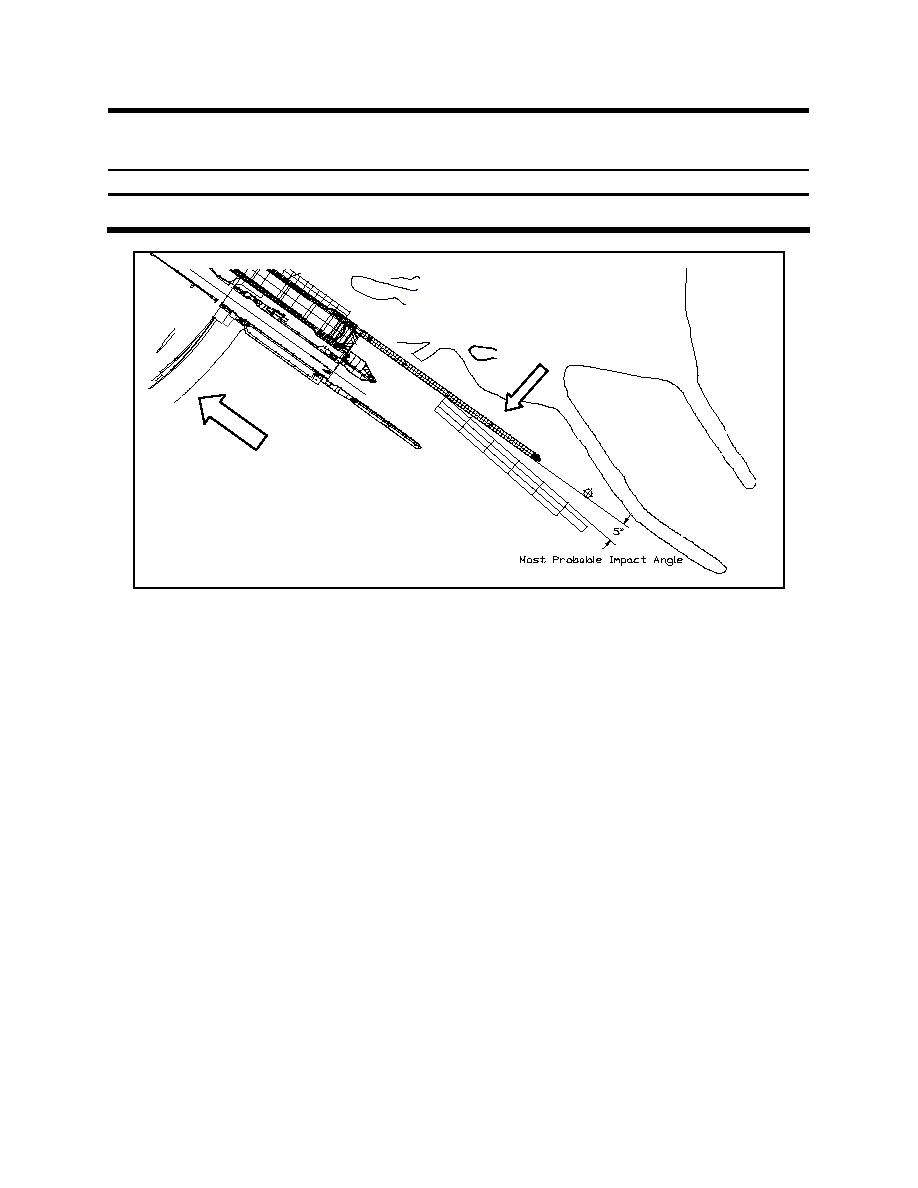

Figure C-12. Upper landside guide wall at Kentucky Locks

(2) Therefore from this design it would be anticipated that the approach angle can be expected to

have a wider degree of variation than was estimated in either the Olmsted or Winfield examples above but

the approach velocities can be expected to be lower. A 1:120-scale navigation model was constructed at

ERDC, but no impact experiments of the upper approach walls were conducted as part of the modeling.

Instead the final design incorporated the use of data from the Olmsted approach walls design since both

designs incorporated floating guide walls. The experiment data from Olmsted was then adjusted based on

the opinions from tow captains that utilize the locks as well as engineering judgment from District

hydraulic and structural engineers. The distributions for impact and forward velocity of the barge are

shown in Figures C-13 and C-14, respectively. The distribution for tow weight was taken from the OMNI

database and is shown in Figure C-15. Table C-3 shows the statistical parameters used for the design of

the upper guide wall.

d. Marmet Upstream Guide Wall, Kanawha River, Marmet, West Virginia (Patev 2000 and Design

Memorandum, Marmet Upstream Guide Wall, Huntington District, 1999).

(1) The Marmet upstream guide wall structure consists of 14 concrete drilled piers spaced at 23 m

(105 ft) center to center and a sheet-pile nose cell, which support 15 precast concrete beams. Figure C-16

shows the layout for the upper approach walls at Marmet. Each pier is constructed of two 2-m- (6-ft-)

diameter drilled shafts with cast-in-place cap beams to support the precast wall beams as shown in

Figure C-17. A thrust block is provided at the cap beam to transfer barge impact from the beam into the

shafts and nose cell. The hollow, rectangular beams have an outside dimension of 3 m by 3 m (10 ft by

10 ft), and the weight of each of the precast beams is approximately 450,000 kg (495 tons).

C-9

Previous Page

Previous Page