ETL 1110-1-163

30 Jun 96

walls. Depending on the depth of the trench, typical

(b) Backfill soil materials. To obtain a low

permeability (typically 1 10-7 cm/sec or less) S-B

excavation equipment may include extended reach

backfill mixture, soils with an appreciable amount of

backhoes, clamshells, or draglines. For depths less

fines (preferably plastic) are necessary. USACE

than about 20 m (70 ft), backhoes are generally most

guide specification CEGS 02444 provides the follow-

efficient. After excavation, the slurry filled trench is

ing gradation criteria for backfill soils:

backfilled with a soil/bentonite/water mixture engi-

neered to create a low-permeability cutoff wall (1

10-7 cm/sec to 1 10-8 cm/sec). U.S. Army Corps

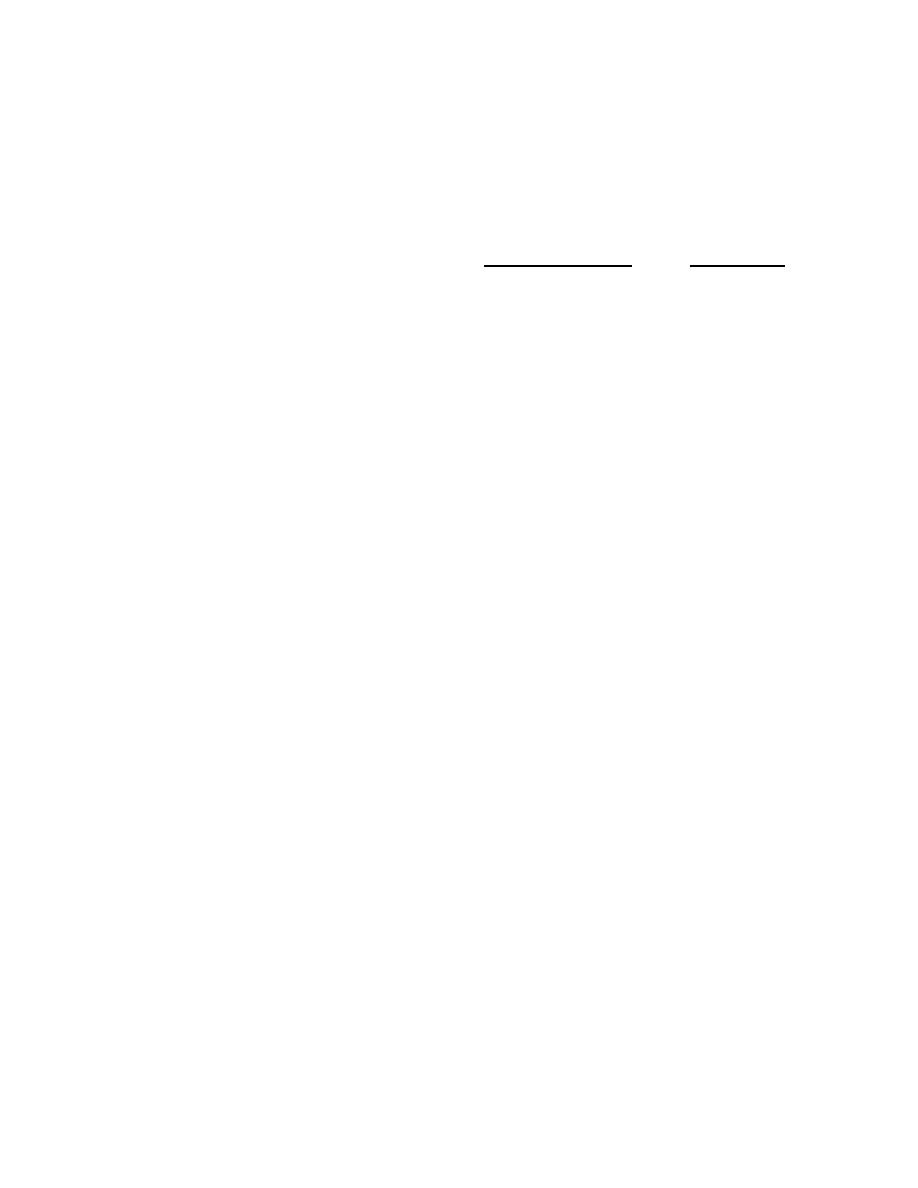

Screen Size or Number

Percent Passing

of Engineers (USACE) guide specification

(U.S. Standard)

by Dry Weight

CEGS 02444, Soil-Bentonite Slurry Trench for

HTRW Projects, should be used in the preparation of

75 mm

(3 in.)

100

plans and specifications for S-B slurry walls.

4.76 mm

(No. 4)

40-80

0.42 mm

(No. 40)

25-60

74 uM

(No. 200)

20-40

c.

Predesign issues.

(c) Bentonite. Bentonite is a natural clay whose

(1) Geologic subsurface investigation. A slurry

principal mineral constituent is sodium montmorillon-

wall should be keyed into an impervious geologic

ite and is characterized by a very large volume

formation along the entire length in order to avoid

increase with wetting. Bentonites which conform to

potential seepage zones under the wall. Borings are

Section 4 of API Spec 13A typically have been

taken along the proposed alignment of a slurry wall,

treated with small amounts of polymers. Bentonites

preferably before the development of plans and speci-

which conform to Section 5 of API Spec 13A have

fications. These borings are spaced 30 to 60 m (100

not been chemically treated. Nontreated (Section 5)

to 200 ft) apart, depending on the geologic uniformity

bentonites are generally more expensive than Section

and thickness of the key layer. Additional borings

4 bentonites. Bentonites conforming to Section 4

may be taken along the alignment during slurry wall

may be used for construction, provided the necessary

construction to verify assumptions made during

permeability is obtained during compatibility testing;

design. During the design phase, samples can be

however, bentonite which conforms to Section 5 of

taken from the slurry wall alignment borings for use

API Spec 13A is generally preferred. During pre-

in backfill optimization and compatibility studies. In

design, several types of bentonite from various

addition, groundwater levels should be measured

suppliers should be obtained for compatibility and

along the alignment of the slurry wall, and if possi-

backfill optimization testing. USACE guide specifi-

ble, seasonal groundwater fluctuations should be

cation CEGS-02444 requires the following properties

documented.

for bentonite used for slurry wall construction:

(2) Soil-bentonite (S-B) backfill testing and

YP/PV Ratio

API Spec 13A

<3

optimization.

Viscometer

>30

<15 cm3

Filtrate Loss

(a) Borrow sources. During predesign investiga-

Moisture

tions, potential borrow sources for backfill material

Content

ASTM D 2216

<10 percent

should be located and sampled. Soils excavated from

the trench may be utilized for backfill soil. This

(d) Water. During pre-design activities, samples

practice saves the time and money of locating, pur-

of the groundwater and samples of tap water to be

chasing, and hauling borrow soil to the site. It also

used for slurry mixing and other operations should be

eliminates the problem of disposing of the excavated

obtained. Generally, 40 liters (10 gallons) of each

trench material. If the in situ soils are not suitable,

should be obtained for compatibility and backfill

due to problems with gradation or gross contamina-

optimization testing. Since a large volume of water

tion, imported borrow is the only viable option. Soil

is normally required for any slurry trench installation,

characteristics such as classification, gradation, water

an adequate source of mixing water must be identi-

content, permeability, and chemical properties should

fied. The guide specification requires water used for

also be evaluated. If a single borrow area does not

mixing slurry and backfill meet the following

have a suitable soil, it may be necessary to mix two

requirements:

different soils to come up with suitable backfill

material.

B-4

Previous Page

Previous Page