ETL 1110-1-163

30 Jun 96

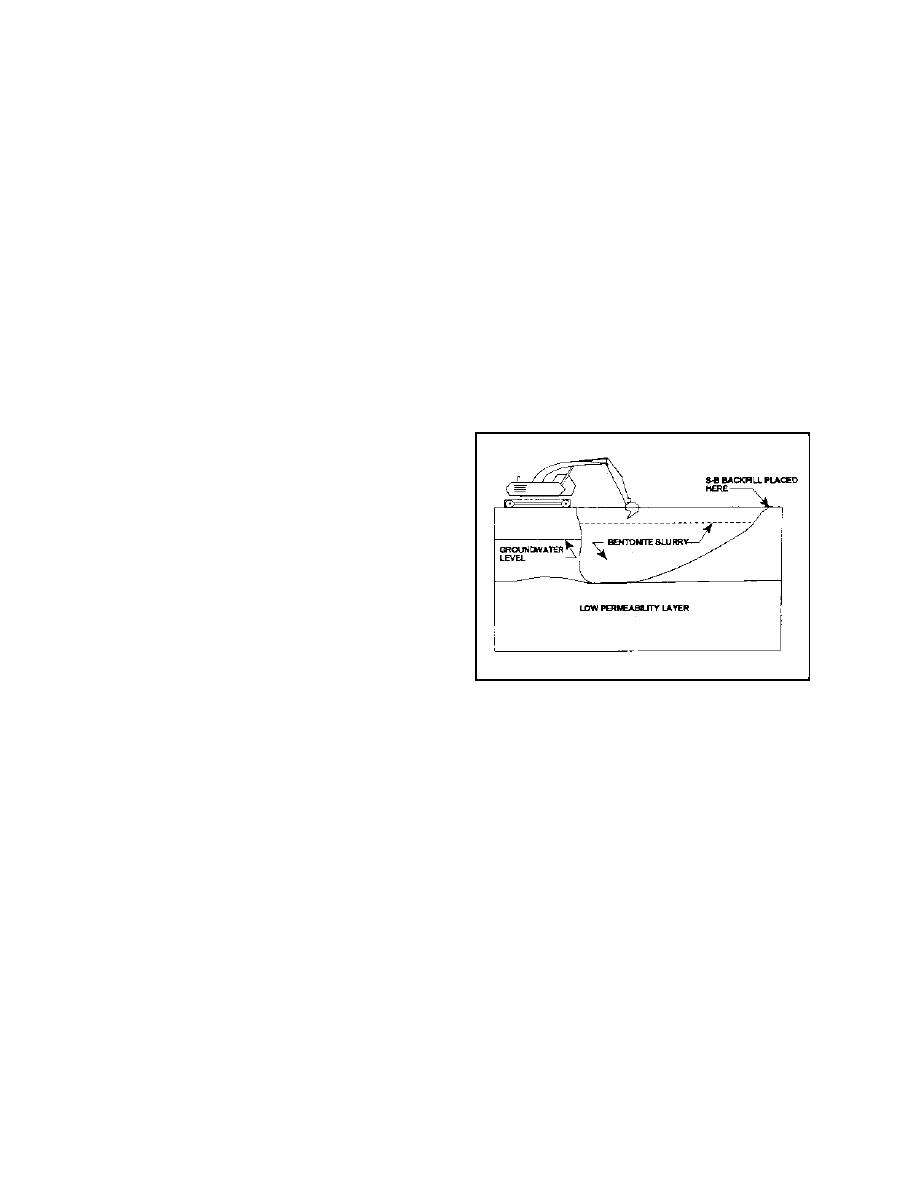

B-3. S-B Slurry Walls

borings should be logged by a qualified geologist or

geotechnical engineer. Surveys should also be

performed to determine the exact location of any

a. History and background. A S-B slurry wall

geotechnical investigations used to define the bound-

(Figure 1), constructed by the slurry trenching

ary of the contaminated area.

technique, is a subsurface barrier made to impede or

redirect the flow of groundwater. This technique was

(2) Site geology. The subsurface geologic con-

pioneered in the United States in the mid-1940's

ditions must be determined and understood prior to

using technology developed by the oil industry.

design and construction of a vertical barrier wall.

Slurry wall construction is a versatile technique that

Some of the geologic data which may be required for

has been used extensively for cutoff walls in dams

design include detailed site stratigraphy, soil or rock

and levees, and is very successful in controlling pol-

type, grain size distribution, Atterberg limits, moisture

lutants, contaminated groundwater, and landfill

content, chemical properties of the aquifer materials,

leachate migrating from waste sites. Because they

degree of weathering, structural discontinuities, rock

have been so successful, the use of slurry walls has

hardness, and rippability.

largely replaced the use of traditional cutoff barriers

such as steel sheet pile walls and grout curtain walls

(3) Hydrology. In addition to understanding the

at hazardous waste sites.

geology, it is imperative to have an understanding of

the site groundwater conditions to define pollution

migration paths. The types of hydrologic information

typically required for design include the following:

location of the water table, recharge and discharge

zones, hydraulic head distribution, hydraulic conduc-

tivity, porosity, extent of geologic units, contaminants

present in the groundwater, and background water

quality. After data gathering has been accomplished,

potentiometric surface maps, geologic cross-sections

with water table elevations, and the depth and extent

of the slurry wall can be determined. A groundwater

model can be used to evaluate and simulate future

groundwater conditions, and several vertical barrier

wall alignments can then be evaluated by the model.

Figure 1. Slurry wall schematic

d. Chemical data requirements. Chemical test-

ing is often required for the features listed below. A

chemist should be involved in these aspects of the

b. General construction. A S-B slurry wall is

project.

constructed by excavating a narrow vertical trench,

typically 600 to 1,500 mm (2 to 5 ft) wide, through

(1) Leachate and groundwater testing.

pervious soils to a relatively impervious key stratum.

During excavation, the trench is filled with slurry

(2) Determination of limits of waste.

consisting of a bentonite and water mixture. The

trench is kept full of slurry to prevent the trench

(3) Contaminated materials handling.

walls from caving or sloughing. The slurry also

develops a filter cake on the walls of the trench that

(4) Compatibility testing of vertical barrier wall

contributes to trench stability and to the low perme-

materials and site contaminants.

ability of the completed cutoff wall. Slurry trenches

have been excavated to depths of more than 30 m

(5) Borrow soil testing (contamination check).

(100 ft) with no caving or sloughing of the trench

B-3

Previous Page

Previous Page