ETL 1110-2-544

31 Jul 95

(3) Field tests. Permeability can be estimated

sand, approximately 100 ft deep. Below this sand

from field pump tests and falling head tests performed

layer is hard tertiary clay. A channel was cut from the

in boreholes.

Mississippi River through the mainline levee to divert

flow to the powerplant. An exit channel leads flow

b. Documented reference. Engineer Manual EM

away to auxiliary overflow channels. The entire site is

1110-2-1901 entitled "Seepage Analysis and Control

surrounded by a levee system which ties into the

for Dams" contains more detailed information on the

mainline levee and the natural levee and backswamp

methods for determining the coefficient of

deposits.

permeability.

b. Purpose of analysis. As shown in Figure 34,

the powerplant receives flow from the Mississippi

River through a diversion channel and could

4-4. Case History: S. A. Murray Hydroelectric

experience differential hydraulic heads up to 26 ft from

Plant

project flood conditions and 41 ft under extreme

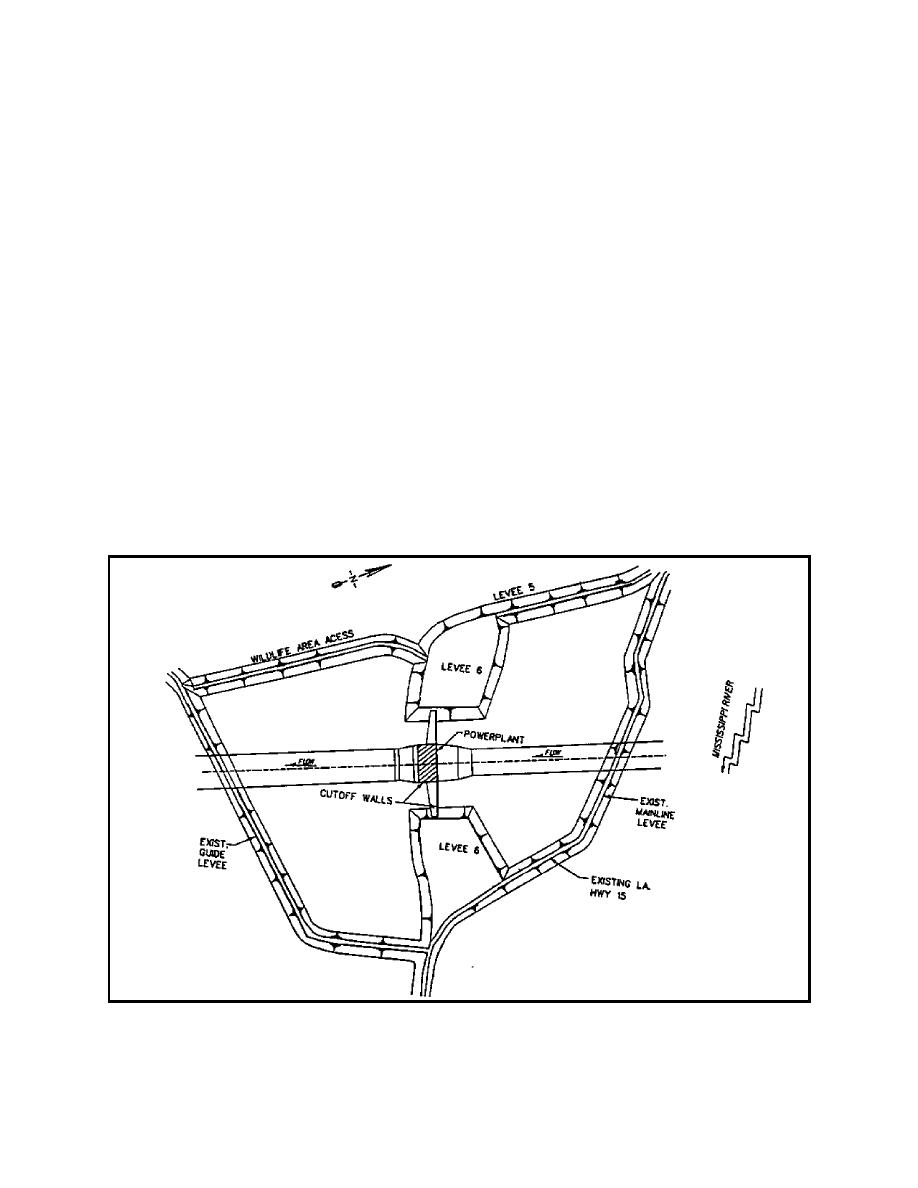

a. Project description. A 2-D plan view

conditions. These heads cause seepage to occur under

seepage analysis of the S. A. Murray, Jr. Hydroelectric

the structure and subject it to uplift pressures. Seepage

Station was reported by Knowles (1992). The power

control measures include concrete cutoff walls and a

plant is adjacent to the

drainage system. These cutoff walls under the

Mississippi River just upstream from the Old River

structure extend through the sand layer to the tertiary

Control Structure.

deposits. The analysis was performed to determine the

seepage and associated uplift pressure beneath the

Plan and cross-sectional views of the site are shown in

powerplant and other structural features (e.g. concrete

Figures 34 and 35. The powerplant is founded in a

channel linings) and to study the effect of the cutoff

medium to very dense layer of fine to medium

walls on the seepage.

Figure 34. Plan view of S. A. Murray Hydroelectric Plant

A-27

Previous Page

Previous Page